On July 19, 2025, the National Motor Freight Traffic Association (NMFTA) will begin implementing a major shift in freight classification, moving toward a density-based system under the National Motor Freight Classification (NMFC) standards. For logistics companies, this shift makes investing in automated dimensioning equipment not just smart—but essential.

What’s Changing — and Why It Matters

Freight classification has traditionally been based on commodity type, which often introduced inconsistencies and confusion. The upcoming changes prioritize density, providing a more standardized and objective method for classification. While not all freight classes are impacted immediately, this transition marks the beginning of a broader move toward density-based pricing.

According to Old Dominion Freight Line, these changes aim to promote fairness and consistency, but they also increase the pressure on shippers to calculate density accurately and document freight measurements precisely.

Can’t I Just Calculate Density Manually?

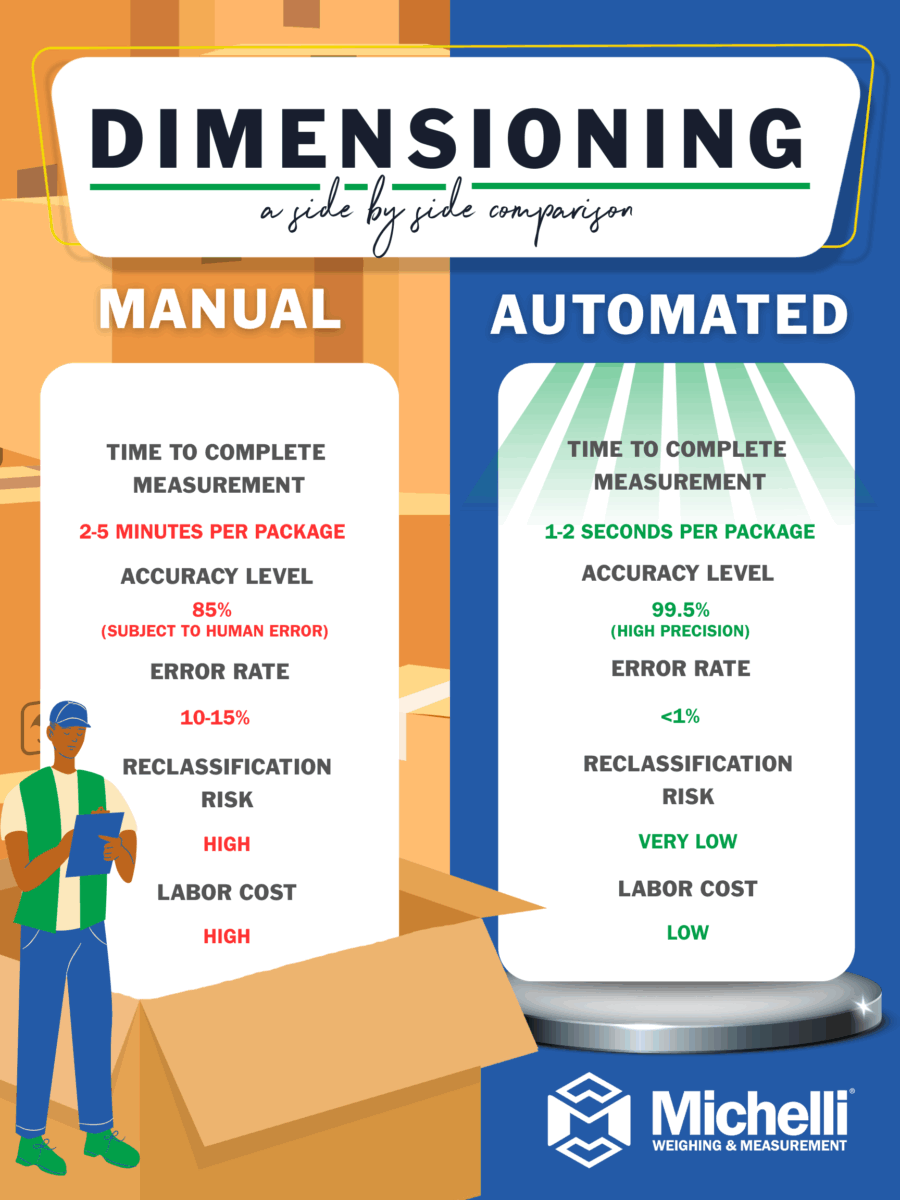

Yes—but manual density calculation comes with risks. Tape measures, calculators, and human inputs are all prone to errors and inefficiencies. If your calculations are incorrect, you could face freight reclassification, unexpected fees, and strained carrier relationships.

Even helpful tools like the Freightquote Freight Class Calculator still rely on manual input, which doesn’t scale well or offer verifiable documentation for carrier disputes.

Why Invest in Dimensioning Equipment Now?

Here’s why more logistics professionals are turning to dimensioning system solutions ahead of NMFC 2025:

1. Speed and Efficiency

Automated systems can capture dimensions and weight in under a second. This eliminates time-consuming manual processes and helps teams handle higher volume with fewer delays.

2. Error Reduction

Automation eliminates guesswork and mismeasurement. The result is consistent, accurate data that supports both compliance and claims resolution.

3. Confidence in Compliance

With measurement data automatically recorded and tied to each shipment, you’ll be prepared for carrier audits and confident in your declared freight class.

4. Productivity Gains

Reducing the time spent on manual measuring allows employees to focus on higher-value tasks—especially important in a tight labor market.

5. Future Proofing

While your freight may not be directly affected today, the trend toward density-based classification is accelerating. Investing now ensures your operation is ready for the future.

FreightWaves highlights the growing importance of automation in LTL operations, including dimensioning technologies that reduce costs and improve logistics workflows.

The Bottom Line

The move toward density-based freight classification is more than just a regulatory change—it’s a shift in how the logistics industry operates. Automated dimensioning equipment helps logistics providers stay compliant, avoid costly mistakes, improve operational efficiency, and stay ahead of the competition.

For companies that want to remain competitive in the post-July 2025 freight landscape, the time to act is now.

Trust the Michelli Team to Help You Prepare for NMFC 2025

Whether you’re operating a warehouse, managing shipping and receiving, or overseeing LTL freight classification, dimensioning equipment isn’t just a nice-to-have—it’s a necessity. Don’t wait until reclass fees and delays start affecting your bottom line. Contact us now to learn about solutions that can help you prepare.

Let’s future-proof your operation today.

Need help navigating the changes?

You already trust Michelli Weighing & Measurement as #YourPrecisionPartner, we are ready to step in this summer as #YourCompliancePartner as well. Reach out to learn more about how dimensioning equipment can transform your shipping process ahead of the NMFTA’s July deadline.