The following post was provided by A&D Weighing. A&D offers a full line of electronic balances, digital scales, weighing indicators and controllers, load cells, and non-destructive measurement equipment. A&D provides tools using precision measurement and controlling technology to add value for customers & contribute to the development of the industry & healthy living.

Weighing equipment & solutions designed for the Food & Beverage Industry

A&D offers weighing equipment & solutions for every stage of the food & beverage manufacturing process. A&D can help with weighing equipment used in research & development, quality control & production, to the tools required for packaging and filling. Use the trusted weighing equipment from A&D to scale up your kitchen with the necessary gear for improved quality, safety & productivity.

Sometimes a Bakers Dozen Won’t Cut It

Too much or too little of a product can have major implications on your bottom line as well as your brand’s reputation. Utilizing weighing equipment, such as static or in-motion checkweighers, throughout your process can ensure that you are not giving away product, and that you are meeting specifications of your customers – avoiding chargebacks and other fees.

Check out our Static Checkweighers

See how In-motion Checkweighers can increase your ROI

Consistency: How Do You Measure a Pinch or a Dash?

Consistency is not only important to ensure a homogenous product in look and feel, but in taste as well. Testing your product throughout manufacturing for moisture content to ensure shelf-life, by sampling for quality control with analytical or precision balances, and testing the viscosities of your liquids ensures that your product meets consumer expectations. Find out how to improve your moisture results with our moisture prep infographic: I Want Better Moisture Results

Not Everything is Dishwasher Safe

Not only do food & beverage manufacturers deal with wet environments, requiring washdown-rated equipment, but the use of harsh cleaning chemicals can cause premature deterioration.

A&D Weighing offers a variety of IP rated products in both the production area and the laboratory to meet your hazardous environment needs — and to prolong the life of your equipment.

See our IP rated products

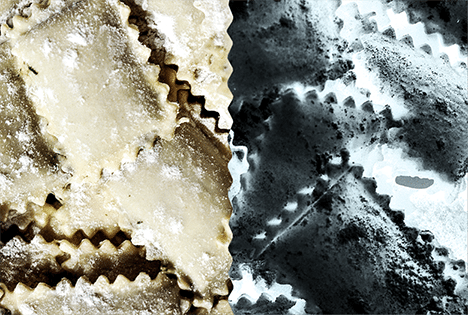

Avoiding & Detecting Contamination

There are various production zones throughout the manufacturing process, which means that are many opportunities for contaminates to make their way into a product. One way weighing and inspection equipment from A&D reduces the risk for contamination is with its stainless steel designs, making the equipment easy to clean between runs and NSF approved for sanitary design. Additionally, inspection by metal detectors can find ferrous material, like stainless steel, and non-ferrous material, like aluminum. X-ray inspection can also detect glass, bone, plastics and other contaminants while simultaneously checking for other product consistency issues, like misshapen or missing product., further ensuring product consistency. Learn more about how product inspection can assure safety and improve quality.

Scalability and Flexibility for Any Recipe

Whether you’re making a few dozen scones or a hundred thousand candies per day, A&D Weighing can help you formulate the right recipe. A&D Weighing offers weighing equipment that spans a large range of capacities, plus the ability to weigh in units that meet your needs, like ounces, pounds or weighing by percent and more.

Sticky Syrups and Sugar

The viscosity of your ingredients influences the consistency, appearance and texture of a product due, so it is an important variable to monitor in most production stages. Whether your are producing sauces, dips and liquid additives, knowing the flow properties can help improve your quality control processes. Get more information on ViscometersWorkflow Integration

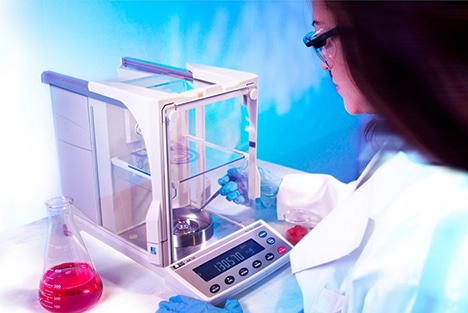

Research & Development

All food and beverage products are conceived in a R&D lab in small batches or test recipes that are perfected and formulated before scaling up in production. At this stage, you may need to utilize products like the following:- Balances ranging from analytical to precision up to high capacity benchtop are all are used in formulation

- Moisture analyzers help R&D determine the right moisture content at every step along the way before production ensuring consistency

Food Lab Quality Control

It is essential to provide consistent product quality while assuring food safety throughout the manufacturing process, which means adhering to GLP standards and food safety regulations.- Analytical and precision balances – combine high resolution SHS weighing technology along with a robust feature-set to provide precise weighing results

- Viscometers are the ideal testing instrument because it provides quick results and is suitable for random spot checks in quality control

Material Receiving

Ensuring full control over quantity and quality of incoming goods.- Bench scales provide efficient identification of raw materials, a basic requirement for controlling your incoming goods and monitoring in-take

- Using moisture analyzers during in-take helps you avoid paying for raw materials that have too much or too little moisture upon receipt

Production

Improve production efficiency with less product giveaway- Static checkweighers can be used to visually verify over/under/okay packages, allowing workers to quickly correct the package without any guesswork

- Indicators and weigh cells provide data acquisition to the product line where metrics like tons per hour can be tracked

- In-motion checkweighers increase productivity and reduce labor, which leads to quick ROI capture; they also provide 100% inspection as all products flow through your line

Packaging & Filling

Assure legal compliance and reduce under and overfill- In-line checkweighers validate fill level and inspect for over/underweight packages, safeguarding against false rejects and allows packers to differentiate themselves through promotion of higher quality standards

- In-line metal detection guards against the smallest of contaminants while minimizing the risk of false rejects.

- In-line X-ray detects more than just metal with advanced features that can find contaminants such as plastic, bone, stone, missing components, non-conforming shapes and more.

Learn more about A&D Weighing Equipment

Let our product specialists help you decide which weighing equipment from A&D is the right fit for your application. Contact your nearest Michelli Weighing & Measurement location today.