What is Hot Dip Galvanizing?

What are its Benefits?

We’ve all noticed that guard rails, light posts and bridge frames are that same gray color with a distinctive pattern, but it’s something that usually goes unnoticed. The reason for this color and pattern is that the metal has been through a process called galvanization. This is by-far, the best possible protection you can provide to steel that will be outside in the elements.

What is Hot Dip Galvanizing?

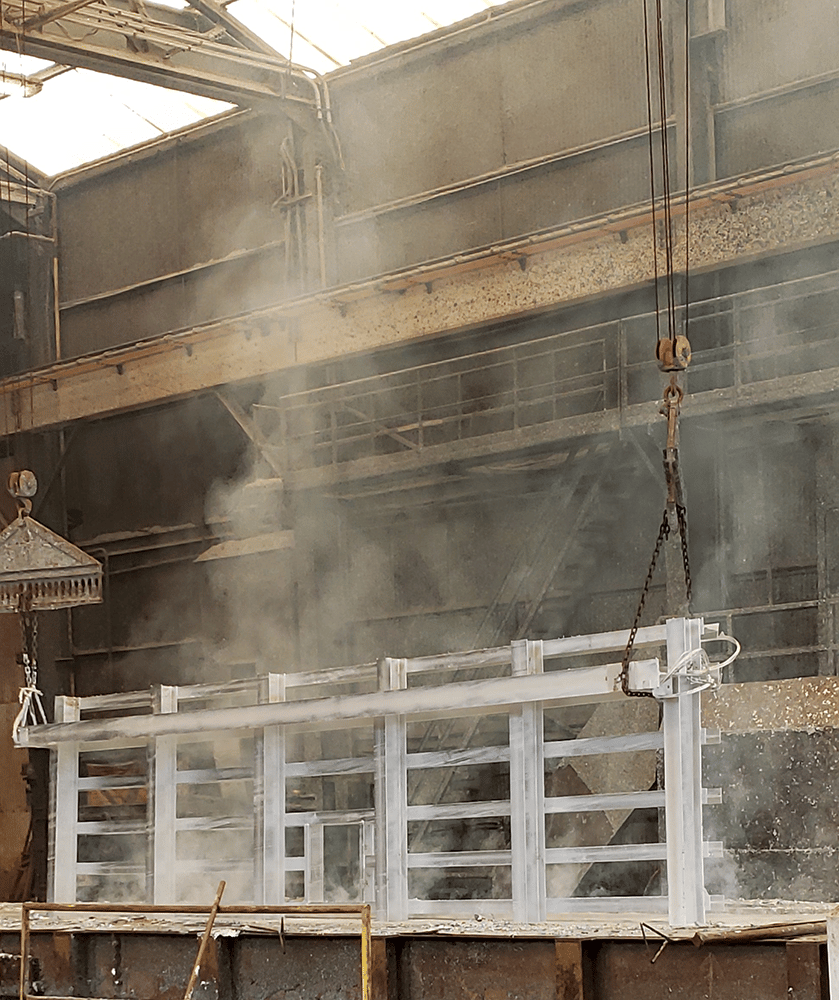

Galvanization is basically the process of coating steel with a layer of zinc. This creates a zinc-iron alloy that’s extremely resistant to corrosion. There’s a whole process involved when galvanizing steel. There’s a handful of steps involved when preparing the steel for the zinc coating. The steel is degreased, rinsed, pickled, rinsed again and then dipped in a flux solution that removes any remaining oxides and adds a protective layer to prevent further oxidation before the zinc bath.

After all these preparation steps are taken, the steel is dried and then dipped into a hot bath of molten zinc. The zinc doesn’t just add an outer layer to the steel like paint, the two metals bond together. Once the steel is dipped in the zinc bath, it’s set aside to cool and then inspected to make sure all areas have been properly coated.

Electro Galvanization

The next most common method of galvanizing is called electro galvanizing. In this process, the protective layer of zinc is applied to steel using an electric current. Electro galvanizing can be a more cost effective way to galvanize steel and it offers more color options, but the zinc thickness can’t be achieved to match the hot dip process.

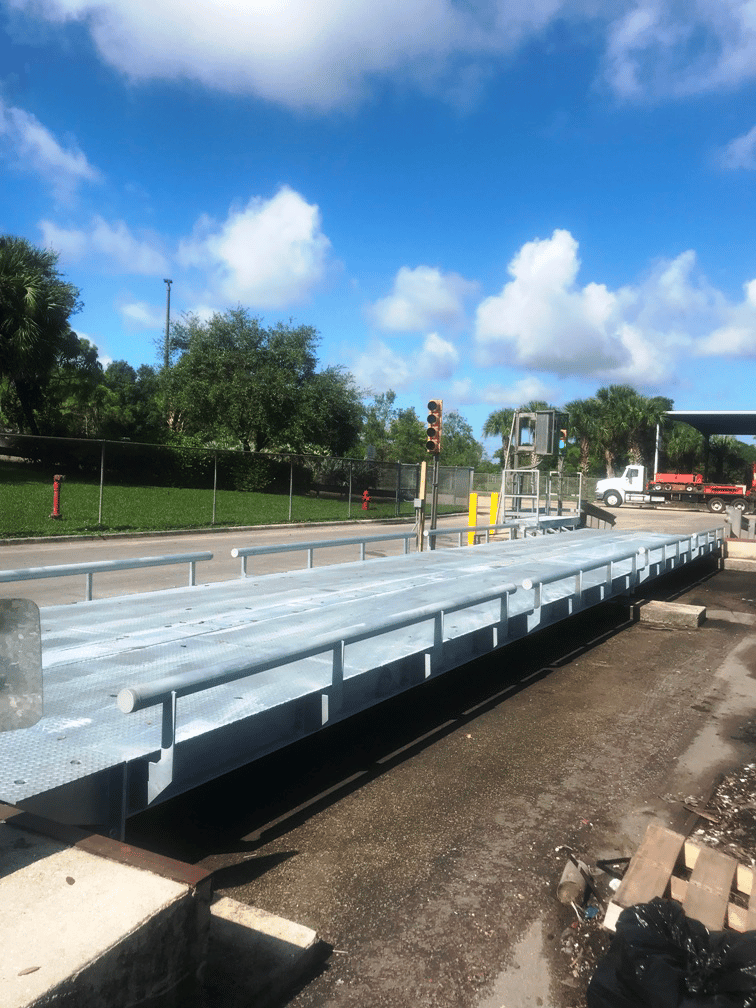

When to Consider Galvanizing for Your Scale

- If you’re in an area where snow (along with the salt used to clear the snow) is a factor

- If you’re near the ocean where saltwater is a factor

- If your scale is in a pit where part or all of the scale can be submerged at times

- If your scale is used to weigh caustic materials

- If you want to extend the life of your significant capital investment

How Much does Galvanizing Cost?

Zinc prices fluctuation, but you can typically expect to spend 25-30% more for a galvanized truck scale vs. a painted one. When considering the total cost of ownership of a truck scale, this cost can be absorbed easily due to the life extension of the scale.

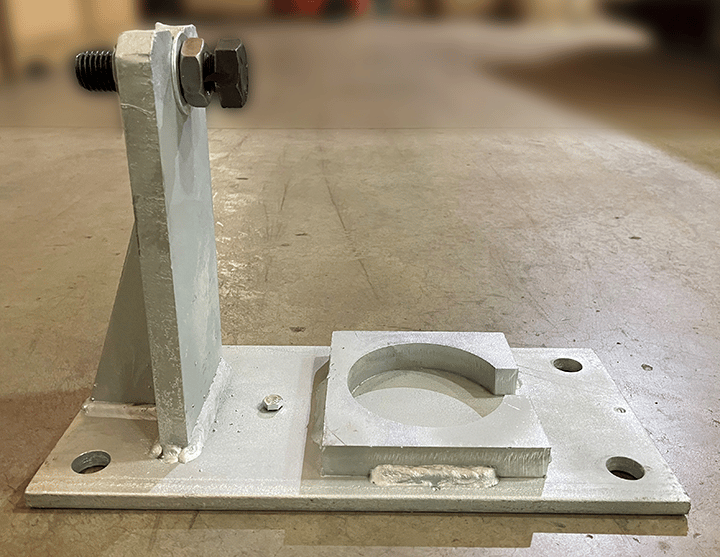

When budgets are tight, there are alternatives that involve galvanization such as only galvanizing the bottom feet or risers of the scale. This is a minimal cost and ensures protection on the parts that are most likely to corrode first because they are the ones usually buried in snow, salt, sand, debris, etc.

Should you Buy Galvanized Scales?

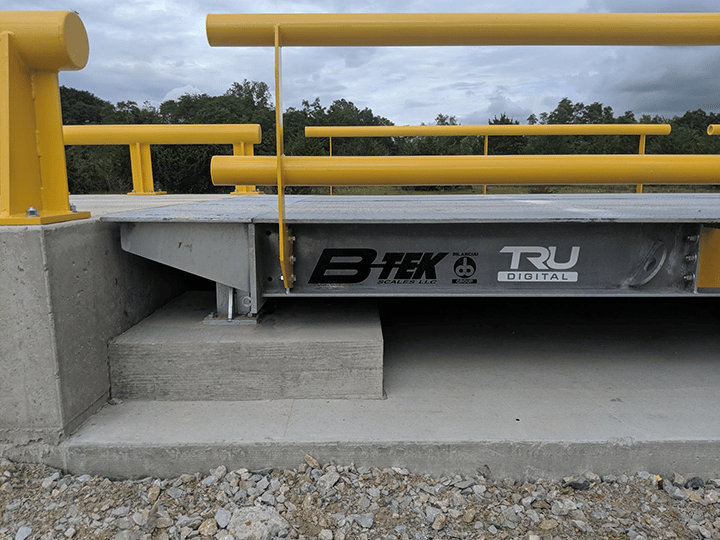

Because almost all static steel structures that are our in the elements are galvanized, it’s a pretty compelling case to show that the process (along with the cost) is worth the investment. If you need any assistance in picking out a galvanized solution that’s right for you, Michelli Weighing & Measurement will work with B-TEK Scales to get you exactly what you need.

Let us help you decide if galvanized equipment is right for you

Let the team of experts at Michelli Weighing & Measurement help find the right equipment for your operation.

The above post was provided by B-TEK Scales, our featured manufacturer this month. From load cells to truck scales, B-TEK has you covered. B-TEK’s multi-generational, highly trained staff of sales professionals, distributors and manufacturing professionals are here to assist you with all your weighing needs.