Multimeters are the key to minimizing extremely costly downtime in industrial environments. Whether it’s a chemical plant performing control system maintenance, or a logistics company ensuring its fleet remains road-ready, accurate electrical measurement tools such as multimeters are imperative to ensuring safety and maintaining productivity.

Though it may be small, the handheld multimeter is among the most valuable diagnostic tools used in the industrial world. In the chemical sector, the multimeter is primarily used to ensure safety in process controls by enabling users to diagnose and troubleshoot electrical issues, and test power supplies. In the transportation and logistics industry, the tool is utilized to maintain the fleet by enabling team members to monitor battery voltage, ensure electrical components are functioning properly, identify shorts or open circuits, and to diagnose engine issues. While the applications differ, the end goal is the same: keep equipment running safely.

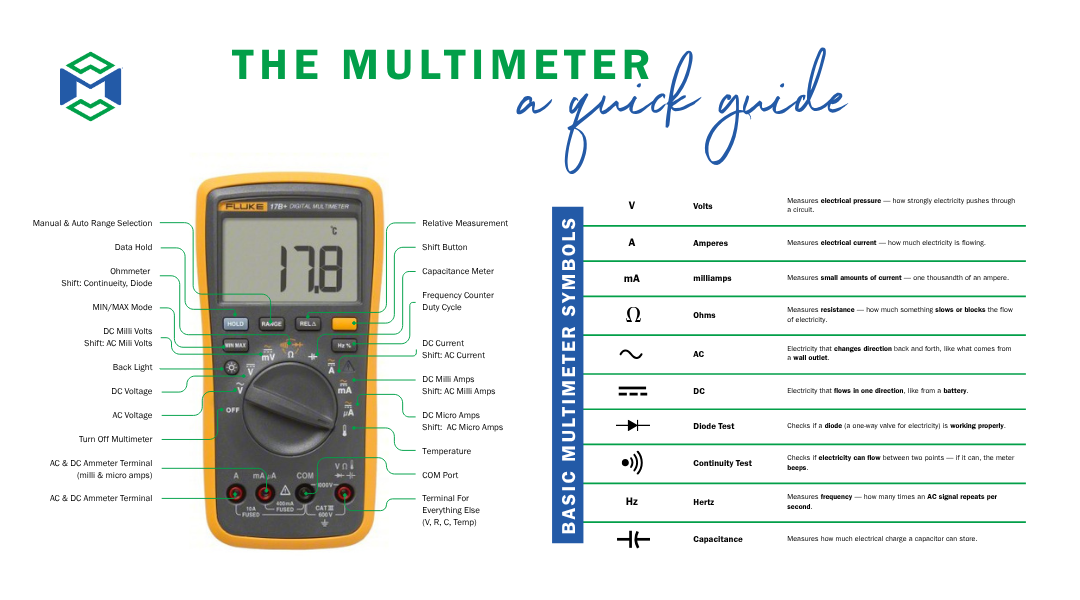

What Does a Multimeter Do?

A multimeter measures voltage, current, and resistance. These tools can also measure capacitance, diode drop, continuity, frequency, temperature and other parameters. In short, the multimeter permits technicians to spot irregularities so they can make adjustments before the issues escalate into bigger problems. In the chemical and logistics industries, multimeters enable technicians to make accurate maintenance decisions, minimizing downtime. As far as electrical tools go, this one is definitely one of the most commonly used.

Transportation and Logistics: Keeping Facilities and Fleets Moving

Ports, warehouses, trucking companies and freight-forwarders rely on a broad range of equipment each day. Conveyors, automated storage systems, electrical infrastructure in vehicles are some of the assets they use. If any of these systems stop working, shipments would be delayed and costs would rise rapidly.

Consider how multimeters play supporting roles at each level:

Fleet electrical maintenance

-

- Technicians use multimeters to troubleshoot electrical systems in trucks, forklifts and other vehicles. They check batteries and charging systems to measure voltage drops, alternator output and starter circuits to ensure reliable starts and avoid batteries failing in the field. Educational articles on automotive multimeter use cover exactly these kinds of checks. (Source: The Automotive Guide to the Multimeter by Kevin R. Gauthier)

- Grounding and wiring verification is another area where multimeters prove useful. High resistance in a ground circuit can lead to lighting or sensor issues. A multimeter helps locate these problems. Trailer and lighting diagnostics also benefit from voltage and continuity measurements taken with a multimeter. Those measurements help validate wiring integrity and avoid compliance issues.

Conveyor & Automation Equipment

-

- Automated conveyors and sortation systems rely on sensors, electric motors and control circuits. Multimeters can be used to identify overload conditions by measuring resistance, current draw and motor voltage. They can help verify communication between devices in automated systems and check PLC I/O signals and control circuit integrity.

Energy Systems & Facility Infrastructure

-

- Warehouse power systems, lighting, HVAC controls and power panels all depend on correct electrical behavior. Electricians routinely use multimeters to test outlets, power panels and lighting systems. When multimeters are paired with power analyzers or thermal cameras, they form the base of a strong energy efficiency or facility-health program. As one white paper on preventive maintenance in transport and logistics notes, planned maintenance is crucial to protecting investment and cutting costs. Technicians record voltage and current readings to ensure constant power delivery and detect trends during preventive maintenance checks.

In logistics, there is increasing attention placed on predictive maintenance of fleets; strategies that use condition-based or predictive data to avoid unplanned downtime. A recent study shows predictive maintenance in logistics fleets reduced downtime by about 50%, maintenance costs by around 40% and equipment failure rates by 60%. ResearchGate The multimeter, a key diagnostic tool, fits squarely into these strategies.

Chemical and Petrochemical: Multimeters Remove Guesswork

In chemical and petrochemical facilities, accuracy and safety are both vital. Explosive atmospheres, high-value production assets and complex process control systems create very demanding environments. Multimeters used here often need to be rugged, intrinsically safe and highly accurate.

- Instrumentation and process control

In process plants almost every sensor outputs an electrical signal that must be validated for accuracy. Many instrumentation loops use a 4-20 mA current loop standard, which technicians measure using handheld meters. Before returning sensors or field instruments to service, handheld multimeters are used to confirm correct output and communication between field device and control room. - Pump diagnostics and motors

Electric motors and pumps move fluids through complex systems in chemical facilities. To detect motor imbalance or other faults that can threaten motor life, technicians measure voltage balance across three-phase systems using multimeters. A meter also supports checks of proper signal consistency when variable frequency drives (VFDs) are applied, and resistance/insulation tests that can identify winding faults before complete failure. - Grounding and safety

Correct grounding and isolation are essential in hazardous environments that may produce explosive atmospheres. Technicians use handheld meters to verify that grounding systems maintain low resistance to earth. In these areas intrinsically safe meters are deployed to protect personnel and equipment. Additionally, multimeters are used to confirm zero voltage during lock-out/tag-out procedures. - Compliance and reliability

Chemical companies include handheld multimeters as part of their calibration, verification and predictive maintenance programs. The broader theme of predictive maintenance as part of “Industry 4.0” comes into play here: equipment measurement, logging and trending enable earlier detection of degradation, avoid shutdowns and improve reliability. arXiv

Reliability Through Measurement: The Common Thread

Across industries, one statement remains true: measurement drives reliability. Rather than relying on guesswork, technicians make decisions based on data gleaned from handheld multimeters.

- A connector with corrosion may show a lower-than-expected voltage reading, flagged early via measurement.

- Degrading insulation or failing windings may show out-size resistance or abnormal current draw, again measurable with the right tool.

- Catching these issues early saves companies thousands of dollars in repair costs and prevents unplanned downtime.

Many industrial facilities now log multimeter readings into digital maintenance systems as part of broader predictive maintenance strategies. The concept of predictive maintenance is described as a method to determine equipment condition and schedule maintenance only when warranted rather than only at scheduled intervals. MT Whether the focus is a truck scale or a refinery control loop, the principle remains: precise measurement leads to reliable performance.

Choosing the Right Multimeter for the Job

Selecting the correct multimeter depends on the application and environment. Key considerations include:

- Transportation and Logistics: Look for handheld meters with durable casings, auto-ranging capability, data-logging features and field usability for technicians working in vehicles or outdoor spaces.

- Chemical and Petrochemical: Priorities include intrinsic-safety certification if used in hazardous zones, ruggedness to withstand harsh conditions, and measurement ranges suited to process signals (e.g., current loops, insulation resistance, VFD diagnostics).

- Across all industries: Safety category ratings such as CAT III or CAT IV matter for electrical work. Ease of use, calibration support and serviceability are also essential.

- Calibration and support: Instruments lose accuracy over time; a proactive calibration and verification program is an important part of assuring reliable measurement.

Partner with Michelli for Precision You Can Trust

Handheld multimeters keep systems running smoothly in shipping terminals and chemical plants alike. These tools make troubleshooting accessible, support safety standards and enable critical production uptime. In any industry where downtime costs money, the principle holds: precise measurement enables reliable performance. Whether you deal with distillation columns or diesel engines, the tool is the same, the objective remains the same.

Choose the right multimeter, support it with calibration, log the data, act on the findings, and you’ll build maintenance programs that keep your equipment moving and your operations running. Michelli can help, every step of the way.

Michelli can help your team measure with confidence.

At Michelli, we understand the challenges of your industry and provide customized multimeter solutions for safety and performance. Rely on accurate measurements to minimize downtime and concentrate on what you do best while our experts help you choose the perfect multimeter for your success.