What is Electrostatic Discharge?

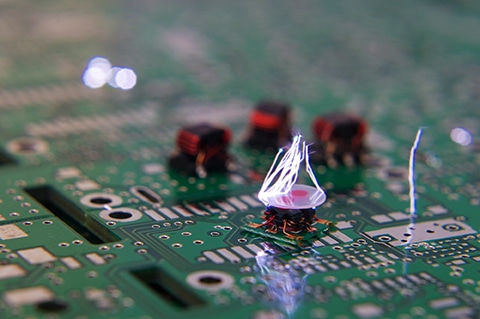

Electrostatic discharge, or “ESD”, occurs when static electricity is suddenly transferred between two electrically charged objects. ESD is incredibly common, and although it isn’t always noticeable to humans, it can still be powerful enough to harm or ruin electronics.

Have you ever walked across a carpeted floor in socks, then touched a doorknob and experienced a shock? That shock was an ESD event. Static electricity builds up when object 1, a person in socks, picks up electrons from object 2, the carpet. Those extra electrons give the person a negative charge. When the negatively-charged person comes into contact with a nearby, positively-charged doorknob, electrons will “jump” from the person to the doorknob. That “jump” sometimes causes a shock, which is an electrostatic discharge event caused by the sudden flow of electricity between two electrically charged objects.

Why is ESD harmful to electronics?

“Electrostatic sensitive devices” refers to those objects that could be damaged by electrostatic discharge. Electronics fit into this category because they contain integrated circuits, which can be easily damaged by the sudden flow of electricity that happens during an ESD event. Also, as technology continues to evolve, our electronics are getting smaller. This process is called “miniaturization,”, and has many advantages. However, smaller electronics mean smaller interior components and thinner protective layers to preserve electricity conducting paths, which are highly sensitive & easily damaged by ESD.

How to protect against ESD

Prevention is the key to protect electronic components against electrostatic discharge. Any protective measures taken to minimize the risk of ESD must provide a grounding method for static electricity, which will naturally accumulate in any environment. It’s important that employees have a safety protocol that details how to ground themselves prior to working with any type of electronics. Another option is to create an ESD protected area that can be used when working with sensitive equipment.

Here are some ways to create an ESD protected area:

- Apply ESD floor coatings

- Use ESD mats

- Install ESD workbenches

- Remove anything that might generate static electricity from workspaces

- Properly store electricity generating devices

- Use antistatic packaging

- Closely regulate temperature and humidity to minimize the possibility of static electricity build up

- Wear grounded, antistatic wristbands when working with electronics

- Install ESD countermeasures at every point where contact with a human or other object is possible, including ESD suppressors, protective filters, test stations etc.

The threat is real

ESD poses a serious threat to electronics. Without protective measures in place, employees could unknowingly cause thousands of dollars in damage by just touching a piece of equipment. The damage might not even be evident at first, but could cause a major problem later. Not to mention, a spark caused by ESD could cause an explosion. Creating an ESD protected area and training employees in proper grounding techniques are important safety measures that should be taken by any businesses dealing with electronics.

At Michelli Weighing & Measurement, we take every precaution to protect your tools and electronics from ESD. Our metrologists employ grounding techniques during calibration, which occurs within ESD protected areas. Michelli service technicians also utilize ESD grounding techniques to protect themselves, our customers, and their equipment during installation and service visits. You can rest assured your equipment is safe with us.