Intrinsically safe, explosion proof & IP ratings explained

What is the difference between “intrinsically safe” and “explosion proof”? How do you remember which IP rating is best for your environment? There are many different terms to describe the level of safety associated with various types of equipment. These ratings and classifications exist for good reason, to help decrease risk & ensure safe working environments. However, the nomenclature can get confusing without some guidance.

Here are simple explanations for each, to help you get the tools that are built for your environment. Purchasing the equipment that was designed to withstand its environment not only helps decrease risk, but also helps to ensure a longer useful life, and therefore a better return on investment.

Intrinsically Safe Scales & Measurement Equipment

Intrinsic safety refers to a technique used in equipment design & electrical wiring. Intrinsically safe load cells, scales, and other measurement equipment has been designed in such a manner that it is incapable of causing an explosion.

Intrinsically safe equipment is made to run on a limited thermal or electrical energy supply, the level of which is not high enough to cause ignition. An intrinsically safe scale, or any type of intrinsically safe equipment, does not release a high enough level of energy to cause an explosion.

Intrinsically safe scales, load cells & other types of equipment are designed for use in hazardous environments that contain explosive, or easily combustible materials. This equipment is designed specifically to decrease the risk associated with using electrically powered equipment in close proximity to these materials.

Explosion Proof Equipment

“Explosion Proof” typically refers to a box, or enclosure of some sort, inside of which a piece of equipment is installed. The explosion proof box is designed so that, in the case of an explosion, the damage sustained by the equipment is contained within the box. For example, an indicator might be installed within an explosion proof box in a hazardous environment. If there is an explosion, the explosion proof enclosure would contain any parts of the indicator that might be affected, ensuring screws, wires and other components remain within the enclosure, decreasing the risk of those parts instead exploding outward, into the environment.

IP Ratings

An IP Rating is short for Ingress Protection Rating. Ingress means entry, so the Ingress Protection Rating on a piece of equipment describes the level of protection against entry of different objects, such as dust or water. The IP Rating lets users know what level of protection the equipment offers, so that they can determine which equipment is best suited for their environment, in an effort to decrease risk.

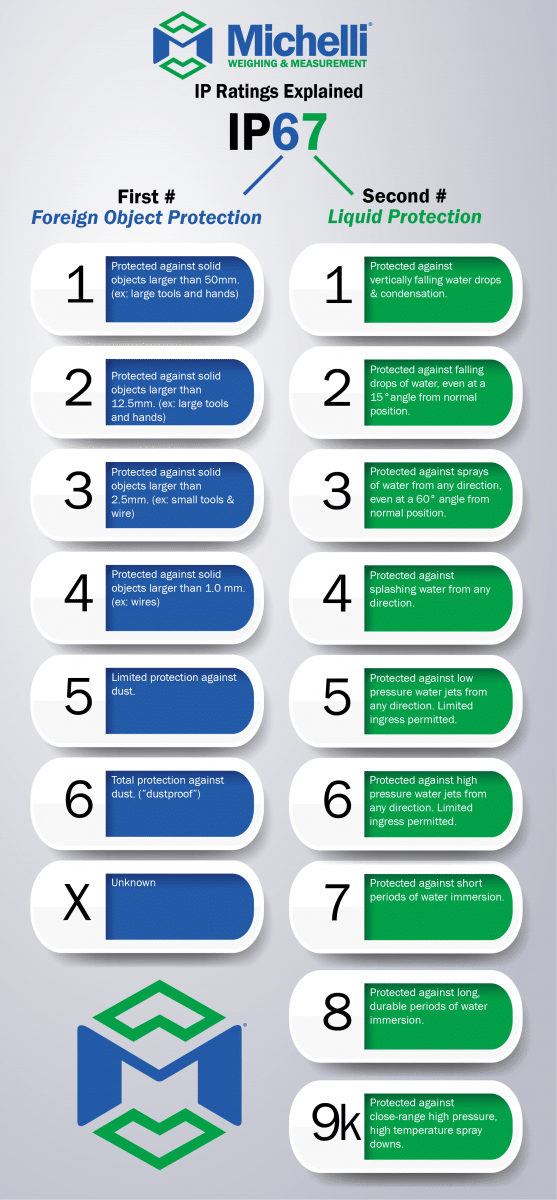

The IP Rating contains the letters IP, followed by 2 digits, and in some cases, 2 digits and another letter.

- The first digit signifies the level of ingress protection against foreign objects, or solids. For example, the first letter might signify that an enclosure offers limited protection against dust.

- The second digit signifies the level of ingress protection against liquids. For example, the second digit might signify that an enclosure offers protection against vertical water drops (such as light rain) & condensation.

Each digit signifies a different level of protection. As the numbers on both the foreign object protection and the liquid protection scale increase, so does the level of protection. Take a look at the chart for an in-depth explanation of each number, and the level of protection it signifies.

Understanding Safety Ratings is Imperative

First and foremost, understanding safety ratings helps us decrease risk & maintain safe, stable working environments. That being said, purchasing the right equipment for your environment helps ensure that you get the longest useful life, and therefore the highest return on investment. Purchasing equipment that is not rated to safely perform in your environment could cost you in the long run. Let our product specialists help identify the right equipment for your situation. Contact your nearest Michelli Weighing & Measurement location today and tell us about your environment and your application. We’re nearby & ready to help.

Speak with a Michelli Weighing & Measurement Expert Today

Give us a call & let our product specialists help you find the right equipment for your environment, your application, and your budget, today.