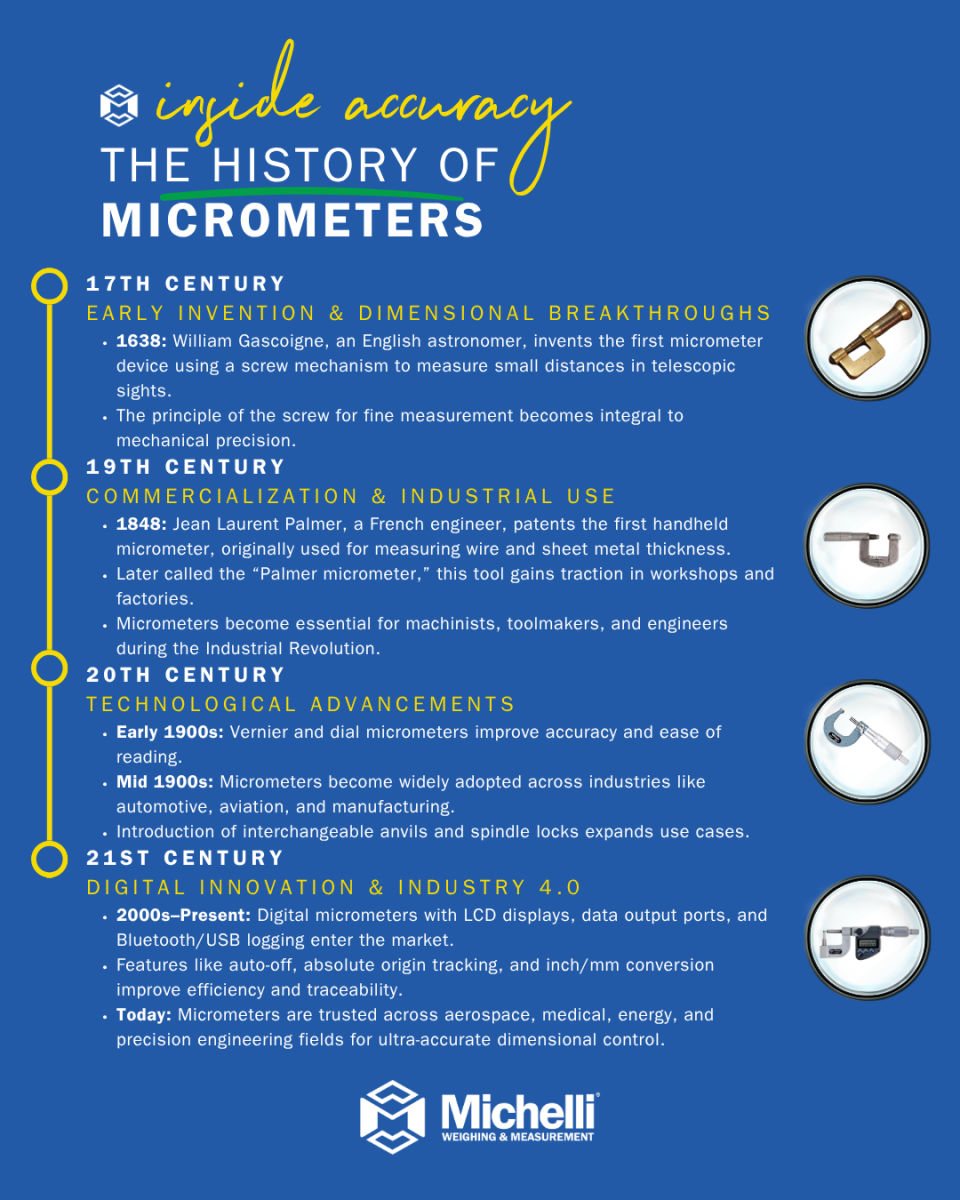

A Brief History of the Micrometer

The micrometer, sometimes called a “micrometer screw gauge,” has been a cornerstone of precision measurement for over two centuries.

- Early Origins: The concept dates back to 17th-century French scientist William Gascoigne, who adapted a screw-based measurement system for telescopes.

- Industrial Adoption: In 1848, French inventor Jean Laurent Palmer introduced the handheld micrometer design, which was refined by Joseph Brown and Lucius Sharpe in the United States.

- Modern Micrometers: Today, micrometers include digital, wireless, and even Bluetooth-enabled models that integrate directly with quality control software.

How Micrometers Work

Micrometers use the principle of a finely threaded screw to measure with extreme precision.

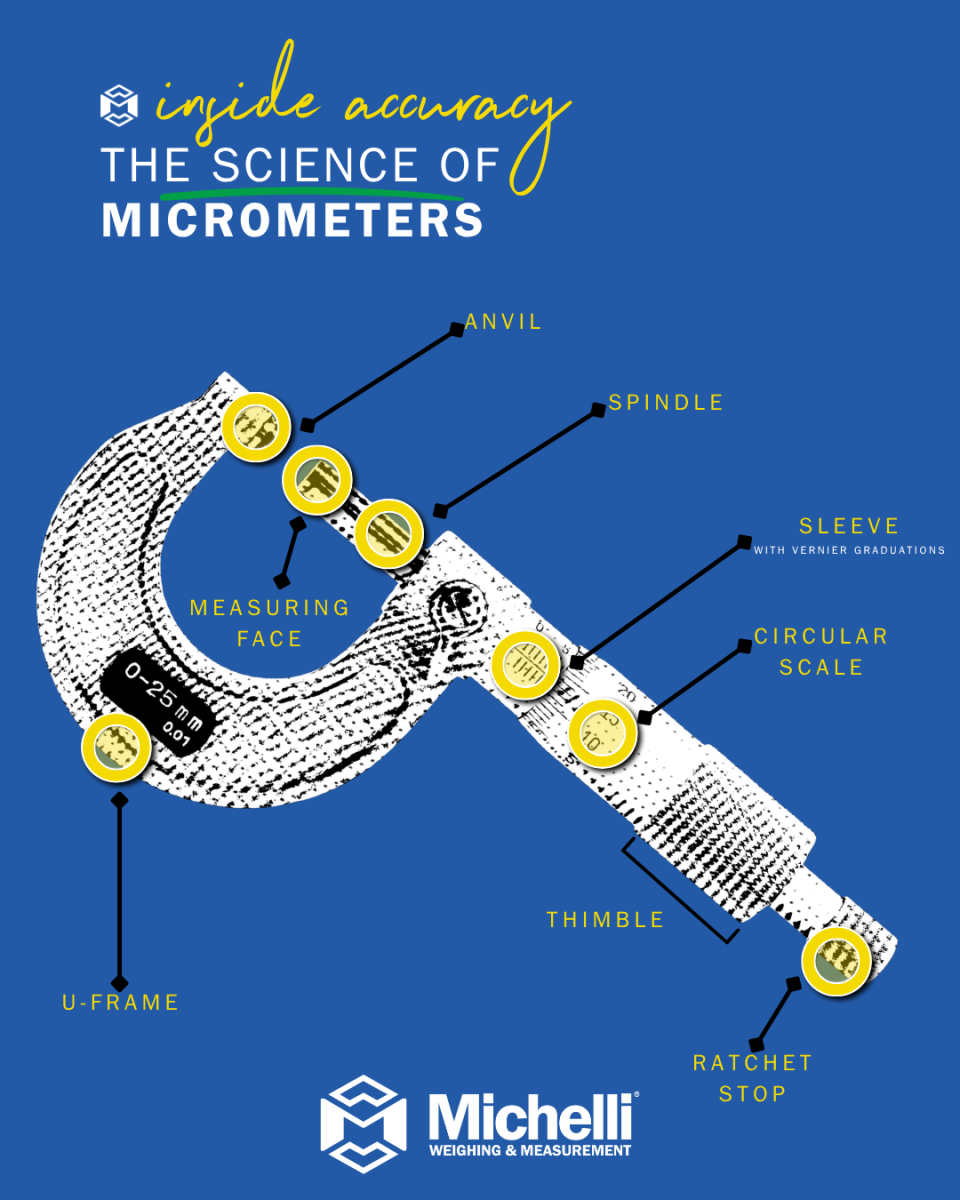

Core Components:

- Frame: A rigid C-shaped body for stability.

- Anvil & Spindle: The object is placed between these measuring faces.

- Thimble & Sleeve: Rotating the thimble moves the spindle toward or away from the anvil.

- Scale or Display: Mechanical micrometers use engraved scales; digital models have LCD screens.

- Resolution: Most mechanical micrometers measure to 0.001 inches (0.01 mm); some digital versions go even finer.

Types of Micrometers

Outside MicrometersFor external dimensions |

Inside MicrometersFor internal diameters |

Depth MicrometersFor depth measurements |

Specialty MicrometersBlade, tube, and screw thread |

Micrometer Calibration

Accurate readings depend on routine calibration:

- Calibration Frequency: Every 6–12 months, or more often in high-precision work.

- Standards Used: Gauge blocks, master rings, or specialized calibration standards.

- Calibration Process:

- Clean measuring surfaces.

- Verify zero setting.

- Test at multiple points within the micrometer’s range.

- Record results for compliance with ISO 17025 or equivalent standards.

Micrometer Maintenance

- Clean Regularly: Remove dust and oil after each use.

- Avoid Overtightening: Use the ratchet or friction thimble for consistent force.

- Store Safely: Keep in a protective case, away from extreme temperatures.

Lubricate Threads: Light oil on the spindle threads prevents wear.

Industry Applications

Manufacturing & Machining

Ensuring parts meet tight tolerances.

Automotive

Measuring brake rotors, engine parts, and bearings.

Aerospace

Checking critical aircraft components.

Metalworking

Measuring sheet metal and wire thickness.

Laboratories

Research and material analysis.

Conclusion

From the earliest screw gauge designs to today’s wireless digital micrometers, this tool has remained one of the most trusted precision measurement devices in history. Regular calibration and proper maintenance keep micrometers accurate — and keep industries running smoothly.

Ensure Your Micrometers Deliver Precision

Schedule a professional calibration or maintenance service today to keep your tools accurate and your operations running at peak performance.