Proper Equipment Maintenance is the Key to Minimizing Unplanned Downtime

Proper equipment maintenance requires ongoing attention to detail. When it comes to weighing & measurement equipment, it’s the little issues that can “snowball” into big problems over time. If users know what to watch out for, and how to easily prevent and/or correct these small issues, it’s much easier to minimize unplanned downtime. The Michelli Weighing & Measurement experts are here to help you get the most out of your investment by teaching you how to properly care for your equipment. Use the checklist below to regularly inspect your weighing & measurement devices & ensure your equipment remains in good working order.

Basic Weighing & Measurement Equipment Inspection Checklist:

1. Check for dirt & debris on top of, underneath, or near the equipment

Debris on or underneath a scale prevents the scale from moving freely, as it was designed to do. It also causes inaccurate weight readings. Just the same, dirt and residue take their toll on equipment. Whether it’s high precision instruments or heavy capacity scales, sticky residue can damage components and affect performance. Taking the time to properly clean your equipment after use not only helps to minimize unplanned downtime, but it’s also a simple way to increase the life of your equipment.

2. Check for standing water, mud or signs of corrosion

Rust causes the slow death of metal equipment. Once rust appears, the equipment begins to decline into the end of its useful life. A great way to prevent rust is to ensure that after cleaning, your equipment dries completely.

Rust causes the slow death of metal equipment. Once rust appears, the equipment begins to decline into the end of its useful life. A great way to prevent rust is to ensure that after cleaning, your equipment dries completely.

We often see mud caked on heavy capacity scales, or trapped beneath the T-belting on truck scales. Mud holds water, so if it’s stuck to a scale, it’s going to cause rust. The same goes for water trapped inside seals or underneath platforms. The longer that water is allowed to sit, the worse for the metal. Remember to remove T-belting when washing down truck scales, to allow the scale & the rubber to dry completely before returning it. Your equipment should be kept clean and dry to function properly.

3. Check for missing parts and pieces.

Missing components are an unfortunate fact of life. Bolts, covers even feet come loose during regular use, or when moving equipment. The sooner you realize a component is missing, the greater chance you have of finding it, or replacing it before any damage is sustained. Each and every component used in the construction of the equipment has a purpose. One missing part could cause all sorts of damage, from putting added strain on other components to producing inaccurate measurements. Regularly checking to ensure that all parts are in place is a great way to minimize unplanned downtime.

Missing components are an unfortunate fact of life. Bolts, covers even feet come loose during regular use, or when moving equipment. The sooner you realize a component is missing, the greater chance you have of finding it, or replacing it before any damage is sustained. Each and every component used in the construction of the equipment has a purpose. One missing part could cause all sorts of damage, from putting added strain on other components to producing inaccurate measurements. Regularly checking to ensure that all parts are in place is a great way to minimize unplanned downtime.

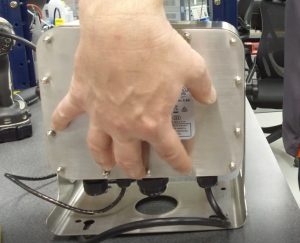

4. Check that all wires are in still in place.

Dangling wires are a safety hazard in more ways than one. A loose wire hanging in a walkway could cause someone to trip or be shocked. Loose wires could also cause electrical damage or some other irreparable damage to your equipment. Ensuring that wires are securely tucked away just good common sense, and an easy way to prevent equipment failure.

5. Check safety components on heavy capacity equipment.

Truck scales and other heavy capacity equipment are typically installed with various safety components. For large equipment, check to make sure your ground rod & wire are visible & in good condition. Also, ensure that your guide rails, approach ramps & coping are in good shape. Each of these parts help to keep your scale safe from different threats, and if they’re not in good “fighting” shape, they can’t protect your equipment.

6. Check output devices to ensure that they can function properly & without interruption.

It’s important to regularly inspect indicators & printers. Test the equipment to ensure that the buttons are working properly, the displays are shining brightly, and the tickets are printing completely. Ensure the power source cable and any other wires or cables are securely connected & all bolts are in place. These small actions can help you minimize unplanned downtime that may be caused by a loose wire or an indicator with a broken display.

Regular Equipment Inspection Gives Users Time to Plan

It’s important to perform these tasks regularly to keep a pulse on the health of your equipment. That way, you have a chance to plan for routine maintenance, downtime, and even replacement when the time comes.

Michelli Weighing & Measurement also provides preventative maintenance (or PM) services, including service agreements that allow you to schedule preventative maintenance at designated intervals, like once a week, every other month, once a quarter, etc. Whether you have our experts taking care of your equipment or not, it’s still a good practice to regularly inspect your devices, and it’s the simplest way to minimize unplanned downtime.

Let us help with preventative maintenance

With service areas in 11 states, our local experts are always nearby. Contact your nearest Michelli Weighing & Measurement location today to schedule an appointment today.