Metrology: The Science of Measurement

While often confused with met-e-or-ology, which attempts to predict whether you’ll need an umbrella or a sunhat, metro-logy is all about ensuring accuracy. It may not sound as glamorous as unraveling atmospheric mysteries, but metrology is just as fascinating and essential to our everyday lives. Metrology provides us with a universally accepted understanding of measurement units and is used globally to uphold the integrity of the readings produced by measurement equipment.

From the moment we wake up in the morning, until we go to bed at night, metrology is silently used behind the scenes to ensure that the measurements upon which we rely daily are dependable. It plays a crucial role across various industries, from manufacturing and engineering to healthcare and scientific research. Metrology utilizes many methods, tools, and standards that ensure measurements accurately represent the quantities being assessed.

A Reliable Foundation

Metrology is used to provide traceability, accuracy, and consistency of measurement equipment worldwide. It helps to provide validity and prevent discrepancies between measurement readings. Metrology sets the framework for reliable and consistent measurements across time and space. It establishes a reference point and enables us to trust the accuracy of our measurements.

- Traceability is the key to ensuring the credibility of measurements. It involves establishing a documented unbroken chain of calibration that links the accuracy of a measurement instrument to the SI Units through a National Metrology Institute. By doing so, we can confidently rely upon the measurement readings produced by the instrument.

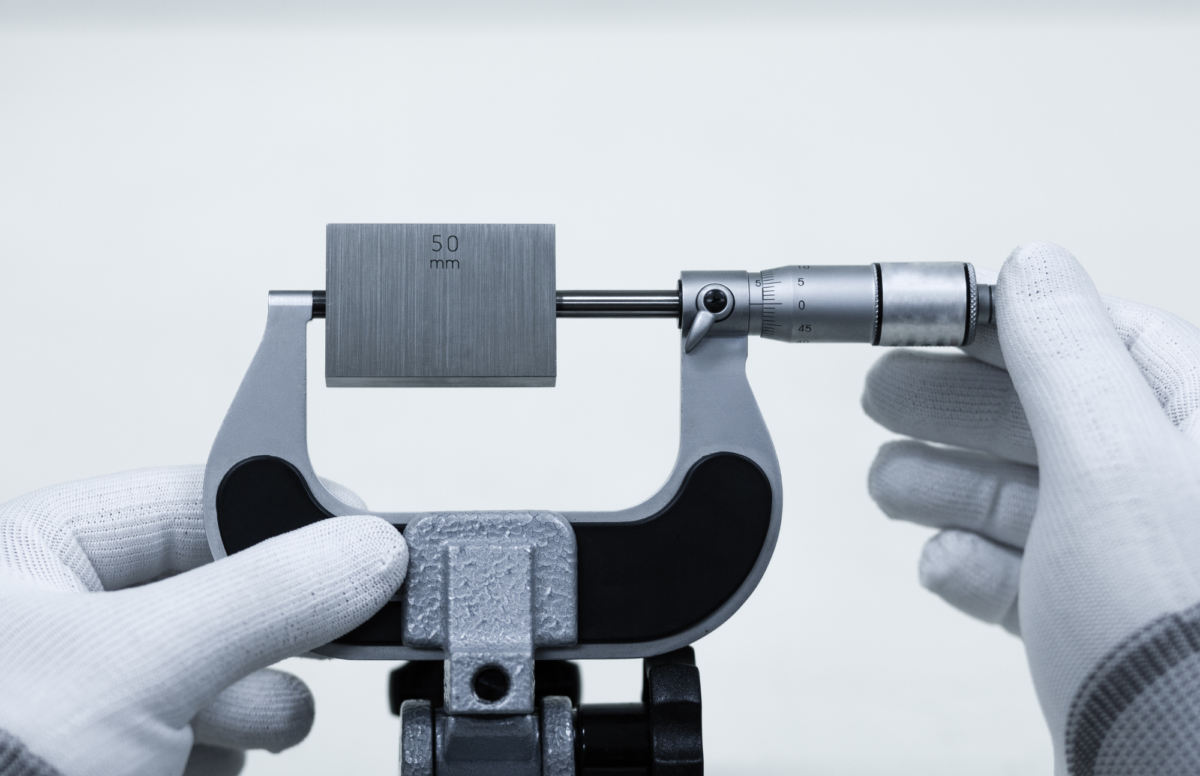

- Accuracy refers to the degree of conformity between a measured value and the actual value of a measured quantity. The use of metrology minimizes errors and deviations by utilizing traceable, accurate reference standards to which calibration technicians can compare measuring instruments, thus enhancing the accuracy of the readings the instruments produce.

- Reproducibility refers to the principle that if the exact measurement procedure is reproducible under the same conditions, it will yield repeatable results. Reproducibility is achieved through standardized procedures, reliable measuring instruments, and adherence to established practices. Metrology is used to define these procedures and ensure the accuracy of these instruments. In doing so, metrology provides reproducibility, enables meaningful comparisons & facilitates collaboration. It also increases the reliability of scientific studies, manufacturing processes, and various other applications.

Metrology provides a solid framework for reliable measurements. It ensures that measurements are not mere approximations or guesses but are instead grounded in recognized standards. This foundation gives us confidence in the accuracy and reliability of the measurements upon which we rely in a range of diverse fields such as manufacturing, healthcare, research, and countless other applications.

How Metrology Affects Industry

Enhancing Quality Control and Quality Assurance

Metrology is vital to quality operations in manufacturing industries. Precise measurements ensure that products meet specified standards and regulatory requirements. Whether measuring dimensions, tolerances, or material properties, metrology enables manufacturers to maintain consistency throughout the production process. The use of metrology helps to ensure product uniformity, allowing manufacturers to confidently say goodbye to sub-par products with wonky dimensions and inconsistent tolerances—and hello to top-notch products and satisfied customers!

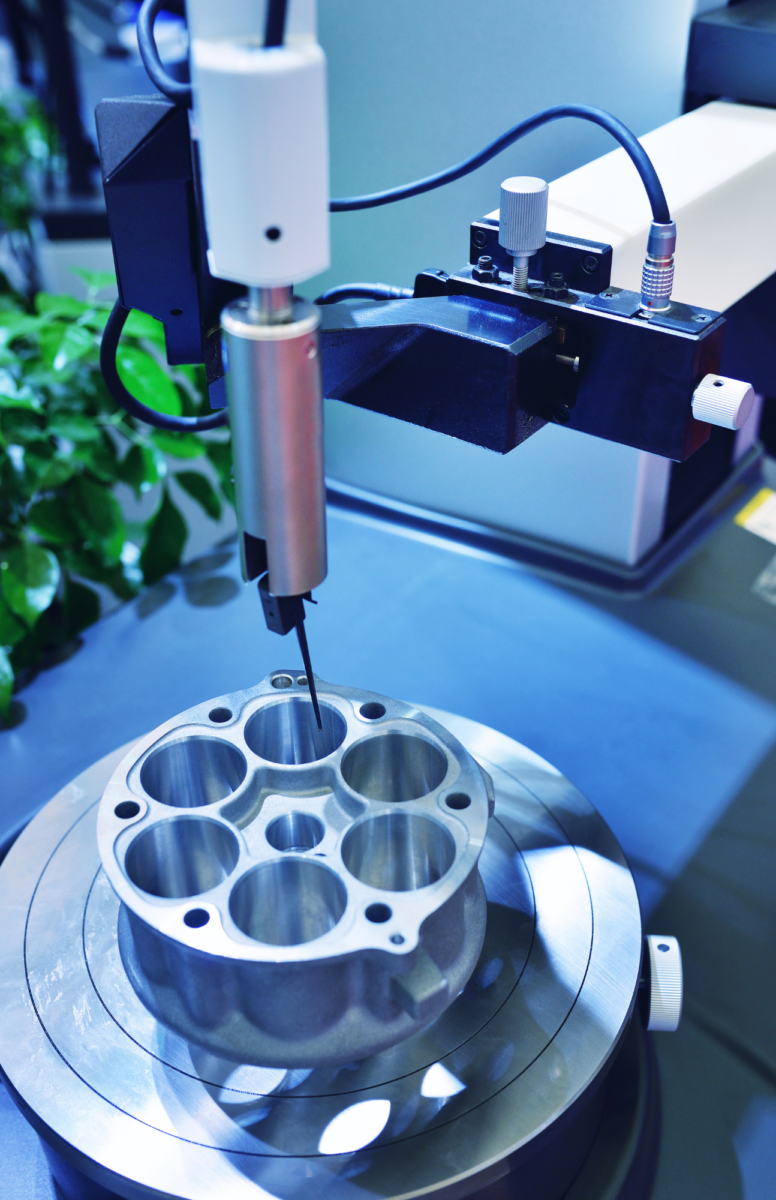

Metrology has led to the development of tools and methods used to provide accurate measurements, such as coordinate measuring machines (CMMs) and optical inspection systems, which allow manufacturers to scrutinize every aspect of production. This attention to detail enables managers to verify equipment performance and proactively schedule maintenance. Metrology also supports quality assurance by providing manufacturers with statistical data and analysis, allowing them to monitor processes and implement improvements.

In a nutshell, metrology brings precision to manufacturing. By utilizing the science of measurement to guide production, manufacturers can confidently deliver high-quality products, strengthening their reputation and increasing customer satisfaction. They are also able to catch errors early, reduce waste, and enhance operational efficiency. With metrology as their trusted ally, manufacturers reduce errors and embrace excellence.

Advancing Scientific Research and Innovation

In scientific research and development, metrology is the cornerstone for advancing knowledge and fueling innovation. It serves as the guiding light, illuminating the path toward accurate measurements that underpin experiments and data analysis. Scientific research depends on the ability to measure and quantify the properties of materials, the behavior of particles, and the intricate workings of the natural world. Metrology equips scientists with the tools and methodologies to produce precise measurements in these endeavors. Whether it’s determining the exact composition of a compound, quantifying the intensity of a signal, or measuring the rate of a chemical reaction, metrology empowers researchers to capture data accurately and reliably.

In the realm of scientific exploration, measurements are more than just numbers. They are the building blocks upon which theories are formulated and tested. The accuracy and validity of measurements directly impacts the credibility and robustness of scientific findings.

Metrology Enables Global Collaboration

But metrology contributes to scientific research beyond individual laboratories and research groups. It enables the comparison and harmonization of results obtained by different teams across the globe through various mutual recognition arrangements (MRA). Metrology fosters collaboration and the exchange of knowledge by providing a common language of measurements. It allows scientists to build upon each other’s work, replicate experiments, and verify results. This collaborative environment, facilitated by metrology, accelerates the pace of scientific progress, and drives innovation.

Moreover, metrology serves as a catalyst for interdisciplinary research and innovation. It is pivotal in establishing accurate measurements to bridge gaps between scientific domains in fields where different disciplines intersect, such as nanotechnology, biotechnology, and renewable energy. By ensuring consistent and reliable measurements, metrology enables scientists to explore new frontiers and push the boundaries of human knowledge.

The impact of metrology on scientific research and innovation cannot be overstated. Providing precise measurements strengthens the foundation upon which scientific discoveries are made, and theories are built. It lends validity to experimental data to bolster the credibility of scientific findings. In the quest for scientific progress, metrology serves as an indispensable partner, helping scientists uncover the mysteries of the universe, one measurement at a time.

Supporting Healthcare and Medical Advancements

In healthcare, metrology ensures that measurements are as reliable as a trustworthy doctor’s advice. It stands as the guardian, ensuring your blood pressure monitor doesn’t play tricks on you, your thermometer doesn’t have a fever, and your medications are compounded to perfection.

Metrology in Clinical Diagnostics

When it comes to patient care and safety, accurate measurements are paramount. From clinical diagnostics to medical device manufacturing, metrology helps ensure that measurements produced by medical equipment are reliable. Imagine a blood pressure monitor that provides inconsistent readings or a thermometer that produces an incorrect body temperature—such inaccuracies can have severe consequences. By adhering to standard procedures, calibration specialists use metrology to ensure that medical measurement instruments provide accurate, traceable readings, enabling healthcare professionals to administer appropriate treatment.

Metrology in Pharmaceuticals

But the role of metrology in healthcare extends beyond the realm of diagnostics. It also supports medical innovation, as well as the development, production, and quality of pharmaceuticals. In the pharmaceutical industry, precise dosage is imperative to ensure effectiveness and patient safety. Metrology helps pharmacists accurately measure active ingredients and verify both potency and purity. It provides structure for pharmaceutical manufacturing processes to ensure capsules are precisely filled and labels accurately depict medication composition. With metrology as their guiding principle, healthcare providers and patients can trust that medications are correctly compounded and will deliver the intended therapeutic results.

Whether it’s through the calibration of imaging equipment, the measurement of biological samples in the laboratory, or the evaluation of novel diagnostic tools, metrology provides a method of evaluation that is both applicable & crucial to a wide range of healthcare-related activities.

Ensuring Fair Trade and Consumer Protection

Metrology is significant in trade and commerce as the guardian of fair transactions and consumer protection. It helps to ensure that measuring instruments utilized in commercial transactions are producing accurate readings. Not only does this prevent customers from being overcharged, but it also protects sellers from giving away more of a product than was purchased. Metrology is crucial in trade and commerce. It is a fundamental pillar of protection that provides transparency & validity to transactions.

In many countries, regulatory bodies enforce laws that dictate the method used to, and the frequency at which, measurement equipment must be calibrated to be used in commerce. These regulations apply to weighing scales, fuel pumps, electricity meters, and other measuring instruments used in commercial transactions. These regulations require a licensed service provider to calibrate the measurement equipment utilizing traceable measurement standards. This service provider utilizes metrological tools & processes to perform the calibration and ensure the readings produced by the measurement device are within the range of tolerance, or the legally acceptable range of variation from the true value. Once this process is complete, the service provider labels the equipment as “legal-for-trade”. Through regular inspections, calibrations, and verifications, metrology helps detect and prevent any attempts to manipulate measurements for unfair advantage. Doing so ensures that consumers receive what they pay for without falling victim to deceptive practices. In this way, metrology also contributes to the broader economy by promoting confidence, encouraging increased consumption and economic growth.

Moreover, metrology is crucial in maintaining a level playing field for businesses. Establishing a standardized measurement framework fosters fair competition and prevents unscrupulous market practices. Companies can rely on metrology to uphold integrity in their transactions, knowing that their competitors are subject to the same rules and regulations. This encourages a healthy and competitive market environment, benefiting businesses and consumers.

The Role of Metrology in Industry

Metrology establishes traceability, accuracy, and reproducibility, which in turn provides stability. It’s there in the background of every industry, establishing a foundation upon which producers & consumers can establish trust. It provides guiding principles that power commerce, fuel innovation, and ensure safety. As technology & industries continue to advance & evolve, metrology will remain in position as the cornerstone that provides support for so many aspects of civilization, and we will develop even more ways to utilize this science.

Need Calibration?

Michelli Weighing & Measurement provides both standard and ISO 17025 accredited calibration on a wide range of measurement equipment, in 31 locations across 11 states. Some services are available on-site. To request a quote for calibration, contact us today.