Plug gauges may be some of the simplest tools in the metrology world, but their role is enormous. These cylindrical measurement tools verify that holes, bores, and threaded components meet exact dimensional tolerances. Whether used in aerospace machining or high-volume manufacturing, plug gauges ensure parts fit, function, and perform as intended.

In this post, we explore the origins of plug gauges, how plain and threaded plug gauges work, where they are used, and how proper calibration and care help maintain accuracy and compliance.

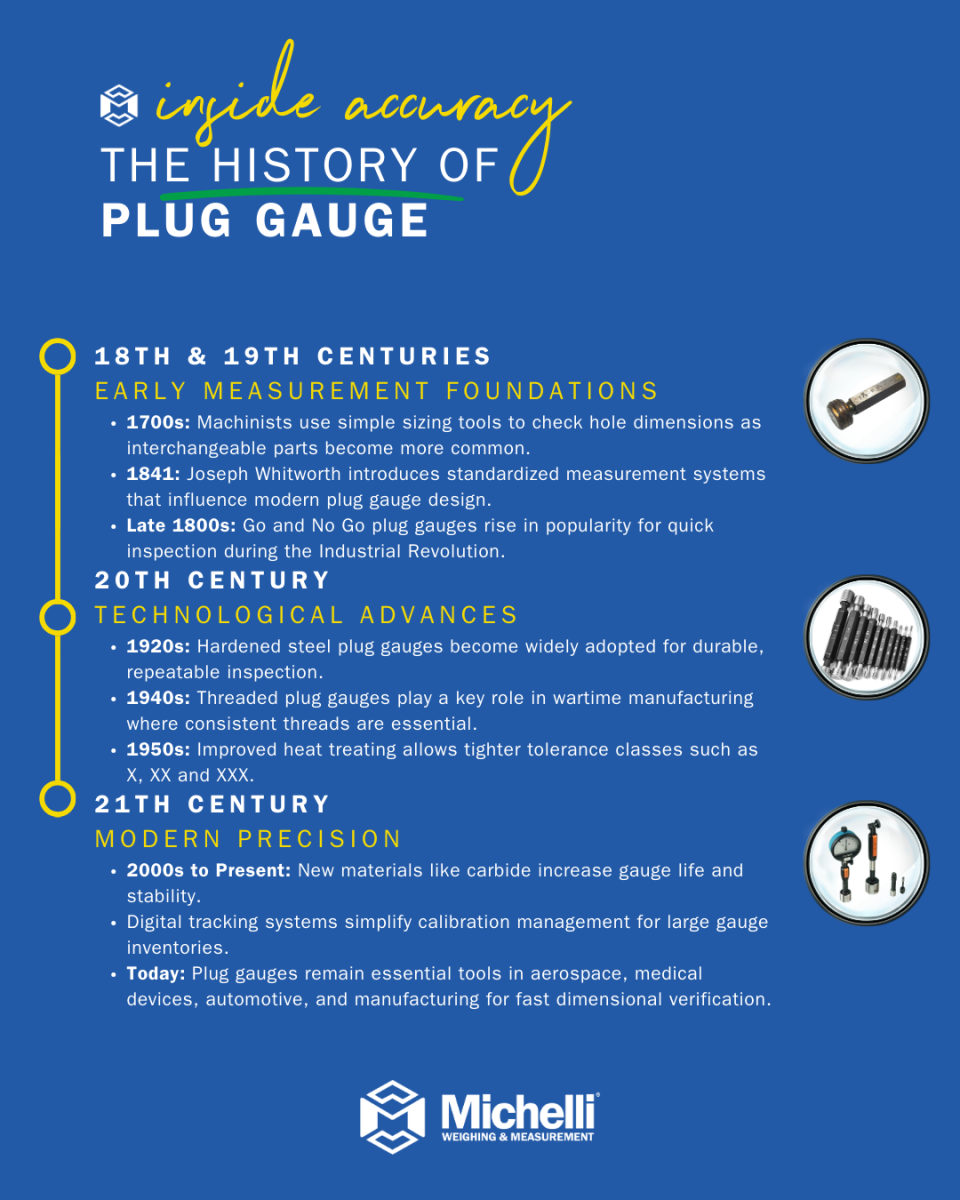

The History of Plug Gauges

Plug gauges originated in the late 19th and early 20th centuries during the rise of interchangeable parts manufacturing. As machining technology progressed, industries needed a reliable way to verify dimensions quickly without relying solely on machinist skill or visual inspection.

Early gauges were simple hardened steel cylinders used to confirm whether a hole was within tolerance, a concept that became standardized with the introduction of GO/NO-GO gauging systems. By the mid-20th century, the ANSI, ISO, and ASME standards we still use today had formalized plug gauge tolerances, materials, and classifications.

Over time, plug gauges evolved to include:

-

- Plain plug gauges (for smooth bores and holes)

- Threaded plug gauges (for internal threads)

- Adjustable plug gauges for custom or oversized applications

- Carbide-tipped gauges for extended wear life in high-volume production

Despite technological advancements such as CMMs and laser measurement systems, plug gauges remain a fast, cost-effective, and reliable method of dimensional verification.

How Does It Work?

Plug gauges determine if a part’s internal dimension meets the required tolerance. They do not measure numerical values — instead, they provide a pass/fail result based on fit.

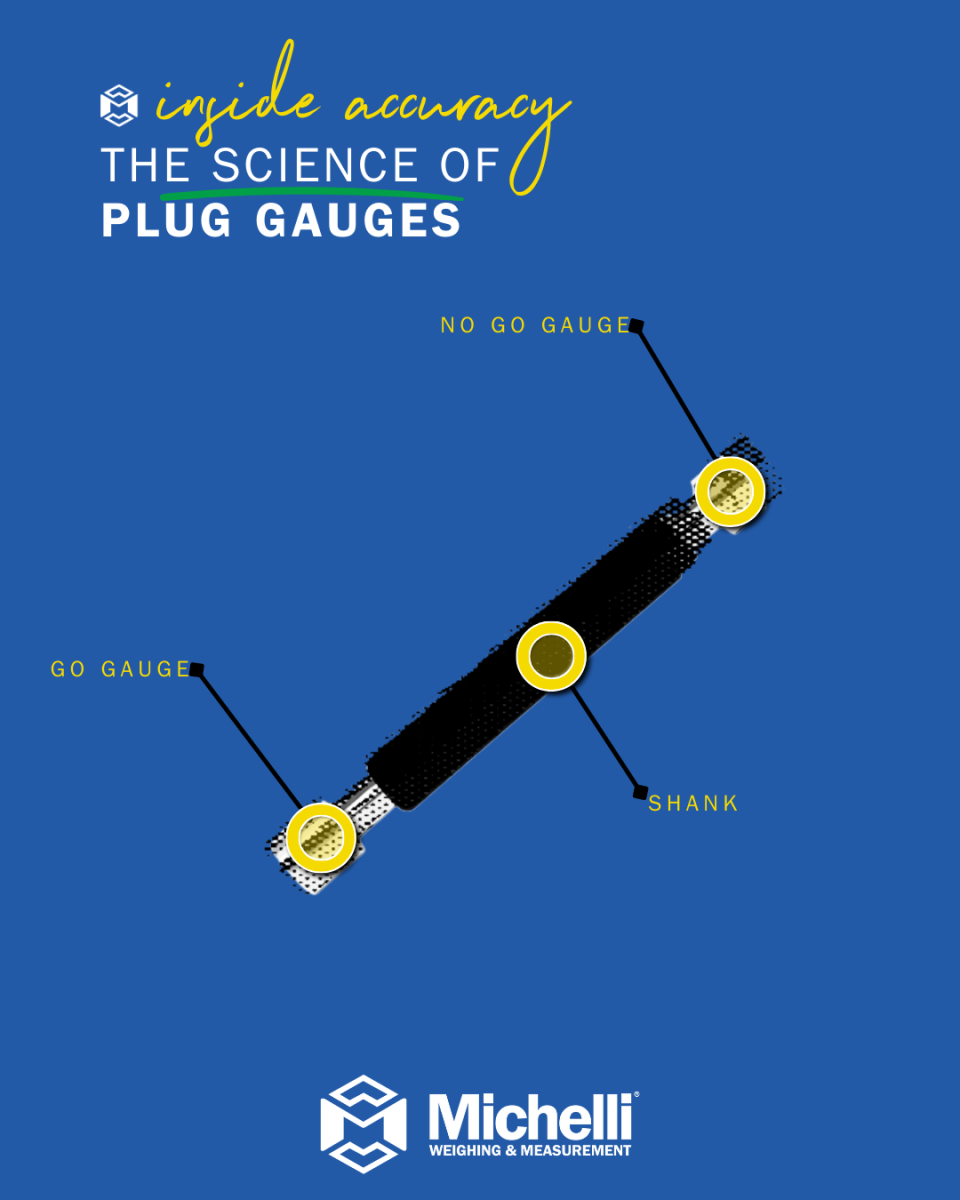

Plain Plug Gauges

Plain plug gauges inspect smooth bores, drilled holes, bushings, and machined components.

They typically include:

-

- GO Gauge: The lower limit of the tolerance. It must fit into the part.

- NO-GO Gauge: The upper limit of the tolerance. It must not enter the part.If the GO fits and the NO-GO does not, the part is considered within tolerance.

Threaded Plug Gauges

Threaded plug gauges verify the accuracy of internal threads.

They are designed to check:

-

- Pitch diameter

- Thread form

- Lead

- Angle

- Minor diameter (indirectly)

Thread plug gauges also use a GO/NO-GO system:

-

- GO Thread Plug: Should screw into the part smoothly for its full length without binding.

- NO-GO Thread Plug: Should not engage more than 1–2 turns.

Thread plug gauges ensure that threaded components can properly mate with external fasteners, essential in industries where failure could cause structural or mechanical damage.

Types of Plug Gauges

Plain Plug Gauges

-

- Cylindrical and smooth

- Used for hole diameter verification

- Available as single-ended, double-ended, or progressive designs

Threaded Plug Gauges

-

- Inspect internal thread dimensions

- Manufactured according to standards such as UNC, UNF, NPT, ISO, and metric threads

Tapered Plug Gauges

-

- Used for tapered bores or seating contact areas

Carbide Plug Gauges

-

- Extended wear life

- Ideal for abrasive materials or high-volume inspection environments

Industries That Use Plug Gauges

Plug gauges appear anywhere precision machining, consistency, and quality control are required.

Manufacturing

Used in machining centers, CNC operations, and production lines to verify bore and thread tolerances for components such as housings, bushings, valves, and precision assemblies.

Oil & Gas / Energy

Threaded connectors, pressure components, valves, and pipeline systems depend on verified thread tolerances to prevent leaks and maintain system integrity.

Medical Device Manufacturing Critical devices such as surgical instruments, orthopedic implants, and dental tools rely on precise hole and thread dimensions for compatibility and safety.

Automotive

Used extensively in engine blocks, transmissions, braking systems, and fuel systems to ensure consistent and safe performance.

Aerospace

Aircraft components, including engine housings, hydraulic systems, and landing gear assemblies, require absolute dimensional accuracy. Plug gauges help prevent catastrophic failures caused by improper fit.

Calibration of Plug Gauges

Regular calibration is essential to ensure plug gauges continue to provide accurate pass/fail assessments. Over time, gauges wear down, especially in high-volume production environments or when used on abrasive materials.

Typical Calibration Steps

- Visual Inspection:

Check for wear, dents, corrosion, pitting, or chipped edges. - Dimensional Verification:

Using a calibrated measuring device such as a CMM, laser micrometer, or supermicrometer, technicians measure:

- Major diameter

- Minor diameter (threaded types)

- Pitch diameter for thread plug gauges

- Roundness and taper for plain gauges

3. Thread Characteristic Testing (for threaded gauges):

Evaluate pitch, lead, flank angle, and thread form using optical comparators or specialized thread measurement instruments.

4. Assessment Against Tolerance Class:

Values are compared against standards such as ASME B1.2, ISO 1502, or ANSI B47.1.

5. Certification:

A calibration certificate documents measurement results, uncertainty, standards used, and compliance.

Routine calibration intervals vary based on usage, but many quality systems require annual or semi-annual verification.

Maintaining Plug Gauges

Proper care extends gauge life and ensures reliable performance.

1. Store Properly

Keep gauges in protective cases or racks, organized by size, class, and type. Never store them loose in a drawer where damage is likely.

2. Keep Gauges Clean

Wipe after each use with a lint-free cloth. Remove cutting oil, debris, or metal particles that can accelerate wear.

3. Apply Light Oil

A thin film of rust-preventative oil protects the tool from corrosion, especially in humid environments.

4. Avoid Forcing the Gauge

If a GO gauge does not fit, do not apply pressure. Forcing can damage both the gauge and the part.

5. Rotate Gauges in Production

Using a rotation system distributes wear evenly across multiple gauges and prolongs calibration intervals.

Michelli: Your Partner in Precision

Michelli Weighing & Measurement provides accredited calibration, repair, and maintenance services for plug gauges, including plain plug gauges and threaded plug gauges. Whether you are managing a single gauge or an entire set used across multiple applications, our experts ensure your tools meet the highest standards of accuracy, safety, and compliance.

From routine verification to ISO 17025 accredited calibration, Michelli helps you keep every measurement precise, because when it comes to reliability, accuracy matters.

Need help selecting or maintaining your plug gauges?

Michelli’s experts are ready to assist with recommendations and calibration services tailored to your industry.