The Michelli calibration lab services & rents torque wrenches

Did you know the Michelli calibration lab provides rental & ISO 17025 accreditation for torque wrenches? The expert Michelli service team offers both standard & accredited calibrations on measurement equipment for the following measurement disciplines: mass, torque, weighing, force, physical/dimensional, temperature, electronic & pressure. Learn more about torque wrenches & the best way to care for your wrench in the post below.

Torque Wrench 101

A torque wrench is a precision measurement instrument. While it may look similar to a solid metal wrench or ratchet, the torque wrench is much more complex internally. There are many types of torque wrenches, including both manual & pneumatic options, but the 2 most common include the beam type, and the click type. Each type has unique features and benefits, but all torque wrenches are used to ensure fasteners are tightened to the correct torque value, which is specified by a manufacturer. Ensuring fasteners are properly tightened is important in every situation from a safety perspective. For example, ensuring a vehicle tire is not over-tightened or under-tightened is crucial to ensuring the safety of the driver.

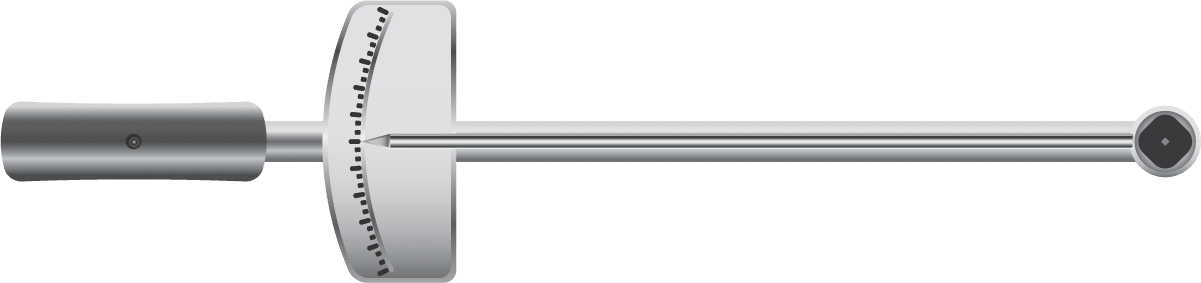

Beam Type Torque Wrench

The beam type torque wrench is the most basic style. This wrench is typically available at a lower price point, but has lower capability in terms of torque range. The beam type wrench requires engagement during use, as the user must monitor the torque value on the scale to know when he/she has hit the desired value.

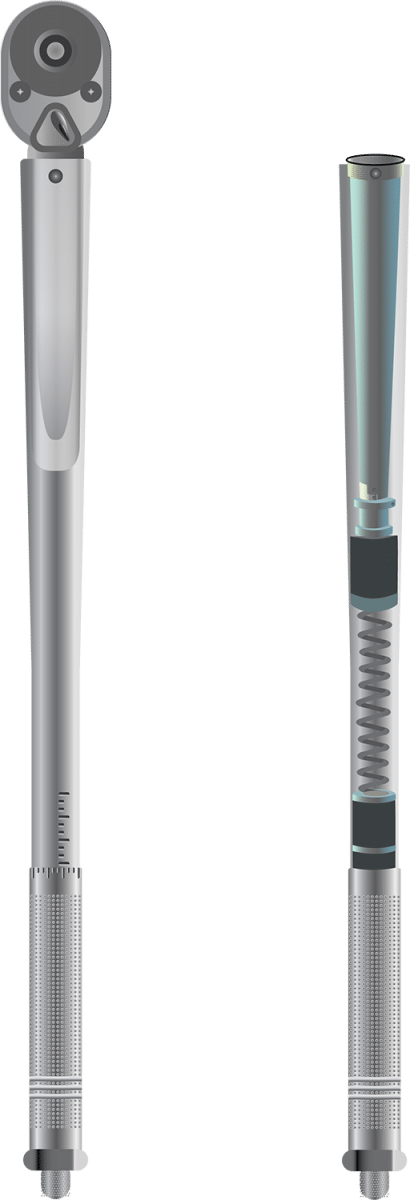

Click Type Torque Wrench

The click type torque wrench (or “clicker” torque wrench) is the most commonly used style & has a higher torque range capability than the beam type. The click type style removes the need for the user to watch the scale during operation to determine torque value. Prior to operation, the user will turn the dial to the desired torque value. During use, once the desired torque is reached, the wrench will produce an audible click, which makes the click type wrench easier to use.

Torque Wrench Terminology

Let’s review a few terms that refer to elements of a torque wrench to ensure the care tips below make sense.

Graduation – a mark on the instrument indicating a torque value

Increment – the value of the difference between adjacent graduations

Full scale or rated capacity – the maximum graduated torque value

Scale – the representation of the range of the instrument, divided into increments marked by numbered and unnumbered graduations

Setting – the amount of torque the instrument is expected to apply

Inside a Click Type Torque Wrench

Your torque wrench is a sensitive precision instrument with complex mechanisms located inside the shaft that can be easily damaged when dropped or used as a hammer.

Tips for Proper Torque Wrench Care

Storage

- Always store your torque wrench in its case, at its minimum graduation. Failure to do so will damage your wrench over time.

- Do not store your torque wrench in an environment that is wet, humid or extremely hot or cold.

Maintenance

- Do not disassemble or calibrate your torque wrench on your own. Enlist the help of an accredited laboratory to maintain the precision of your instrument.

- Check for wear often, particularly around the ratchet. Watch for loose screws and ensure the ratchet can turn freely.

- Have any worn parts replaced at an accredited laboratory.

Use

- Do not use your torque wrench as a hammer

- Do not set your torque wrench any higher or lower than its scale. Only use the torque wrench within its recommended range. Do not exceed the maximum rated capacity under any circumstances.

- Do not use “cheater bars” or any other types of extensions that did not come with your torque wrench. Only use accessories that are supplied by the manufacturer with the torque wrench. Tightening beyond the maximum rating will damage your torque wrench.

-

- Sockets & extensions are ok to use

- To use a crow’s foot & similar accessories requires a formula

-

Care

- Do not write or paint on, or etch into your torque wrench

- Clean your torque wrench with a dry cloth after use to remove dirt & grease

- Do not drop your torque wrench.

-

- If you do drop your wrench, have it calibrated by an accredited laboratory before using it again, as the shock could affect accuracy.

-

Calibration

- Most manufacturers recommend having your torque wrenches calibrated annually or every 5,000 cycles, whichever comes first.

- Setting a predetermined, regular calibration schedule is the best way to ensure your torque wrench remains accurate throughout the year.

- We recommend having your torque wrench calibrated in an ISO 17025 accredited laboratory.

Proper torque wrench calibration is crucial.

Have your torque wrench calibrated by Michelli’s expert calibration technicians

in our ISO 17025 accredited laboratory.