Calipers are indispensable tools in various industries, offering precise measurements for quality control, manufacturing, and research. Their ability to measure inside, outside, depth, and step dimensions with exceptional accuracy makes them essential across countless industries. But not all calipers are created equal—and choosing, using, and maintaining them properly can make a big difference in your workflow.

Whether you’re just getting started or looking to fine-tune your equipment knowledge, this guide will walk you through everything you need to know about calipers, including types, calibration, maintenance, and industry use cases.

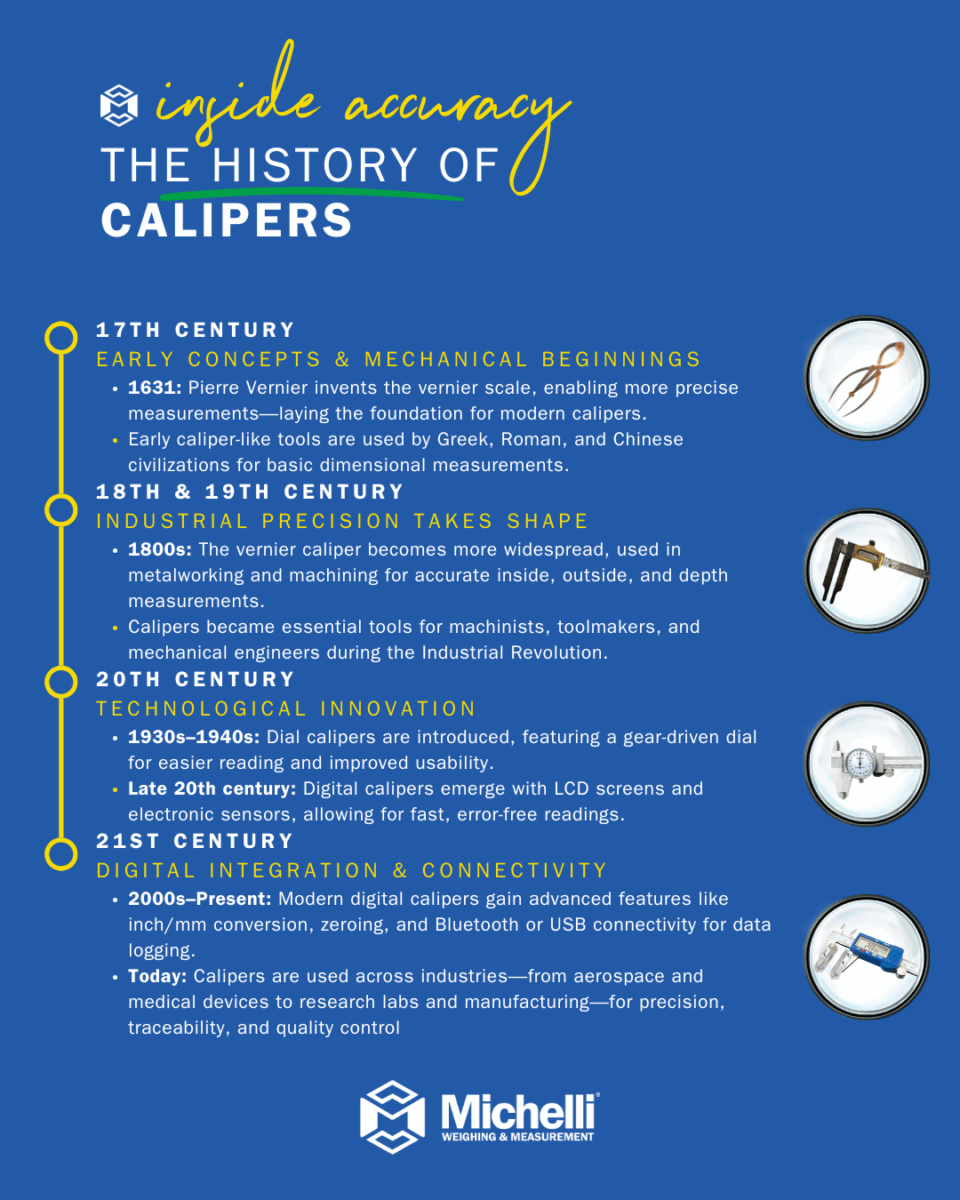

A Quick Look at the History of Calipers

Calipers have been around for centuries. Ancient versions made of wood or bronze were used by Greek, Roman, and Chinese engineers to measure internal and external dimensions.

The real breakthrough came in 1631, when Pierre Vernier introduced the vernier scale, which allowed users to take highly accurate measurements. Today, there are many types of calipers, including digital calipers with LCD displays, and dial calipers, which do not require batteries, for more rugged applications. The present day models are composed of advanced materials that ensure both accuracy and durability, without adding weight.

Types of Calipers (And What They’re Used For)

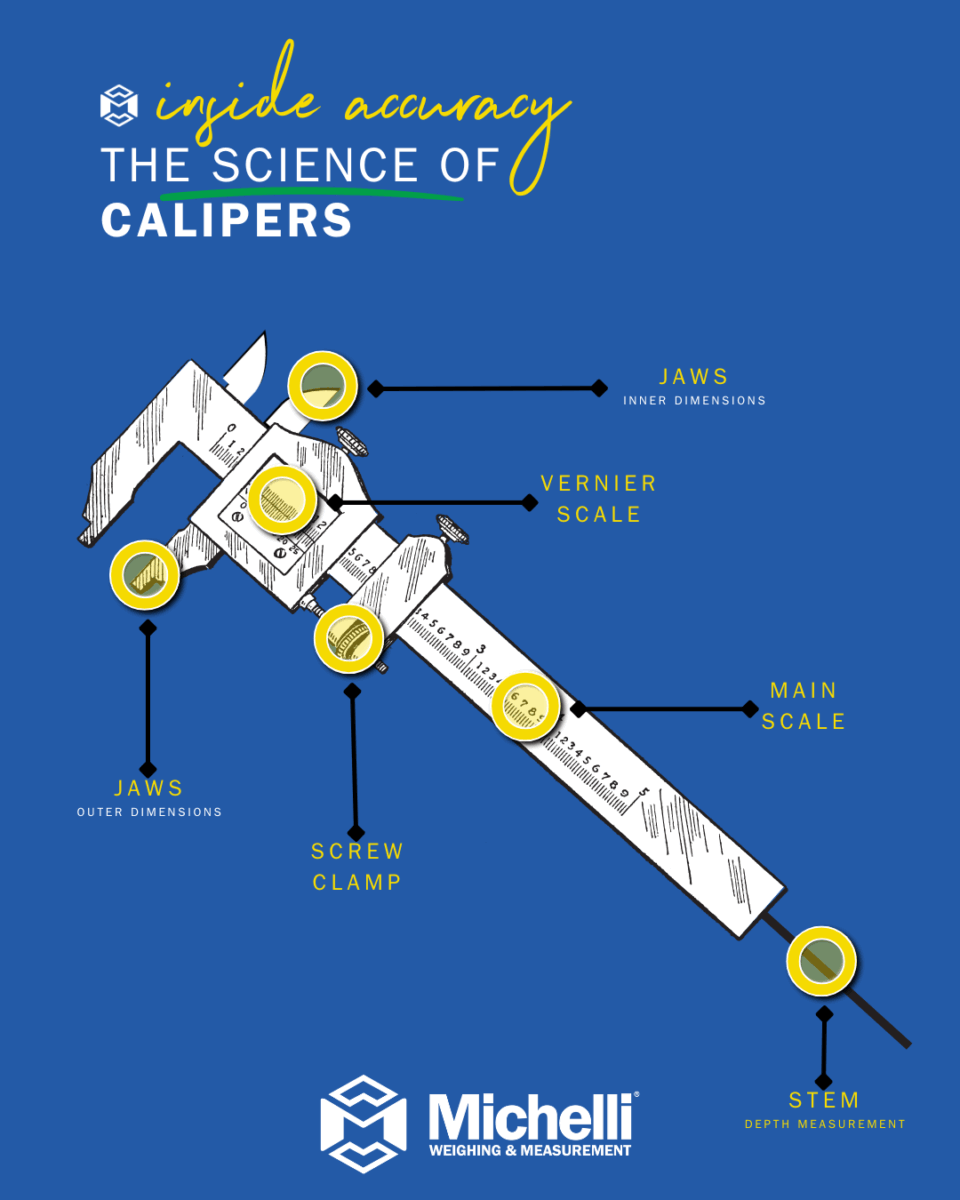

Calipers are precision instruments used to measure the distance between two opposite sides of an object. Unlike basic rulers or tapes, calipers allow for much more refined measurements, often down to the thousandths of an inch or hundredths of a millimeter.

Most modern calipers can take:

- External measurements using the main jaws

- Internal measurements using the smaller top jaws

- Depth measurements with a depth rod

Step measurements from the rear shoulder of the instrument

For a breakdown of the anatomy of a caliper, visit Caliper Basics.

Understanding the different types of calipers—and when to use them—is essential for choosing the right tool for the job. Here are the most common types:

1. Vernier Calipers

These classic manual calipers use a vernier scale to provide high-accuracy measurements. They’re durable, battery-free, and ideal for experienced users who are comfortable reading scales.

2. Dial Calipers

Dial calipers have a mechanical dial indicator that displays the measurement. They’re easier to read than vernier calipers but still require interpretation and regular maintenance.

3. Digital Calipers

Digital models offer easy-to-read measurements on an LCD screen. Most allow inch-to-millimeter conversion and zeroing at any point. They’re excellent for fast, error-free readings and are ideal for both seasoned technicians and new users.

4. Specialty Calipers

There are also inside calipers, outside calipers, divider calipers, and micrometer calipers designed for specific tasks such as measuring grooves, internal bores, or layout marking.

For help selecting the right type of caliper, check out How to Choose the Right Caliper.

How Calipers Work

Calipers work by adjusting a pair of jaws (or a depth rod) around or into the object you’re measuring. The jaws slide along a scale—either vernier, dial, or digital—letting you read the exact dimension.

Digital models do most of the math for you, but even analog versions can measure down to a thousandth of an inch when appropriately used.

How to Calibrate Calipers (And Why It Matters)

Like any precision measurement tool, calipers must be calibrated regularly to ensure accuracy. Calibration checks whether the readings match a known standard and can involve minor adjustments or indicate the need for repair or replacement.

Basic Caliper Calibration Steps:

- Clean the caliper to remove dust, oil, or debris.

- Check the zero point by fully closing the jaws—your readout should show 0.000.

- Use certified gauge blocks to test readings across various ranges.

- Test multiple functions—outside, inside, and depth measurements.

- Document and label calibrated tools with their calibration date and due date.

At Michelli, our calibration services help ensure your tools stay within tolerance and meet industry standards, including NIST traceability.

Caliper Maintenance Tips

Proper care keeps your calipers functioning longer and more accurately:

- Always clean after use with a soft, lint-free cloth

- Store in a case in a dry, temperature-controlled space

- Avoid dropping or over-tightening the jaws

- Replace digital batteries regularly and inspect contacts

- Do not use compressed air, which can drive debris into the mechanism

Routine cleaning and gentle use go a long way toward extending your caliper’s lifespan.

Industries That Rely on Calipers

Calipers are trusted tools in nearly every precision-driven field:

Industry |

How Calipers Are Used |

|

Manufacturing |

Measuring precision aircraft components, engine parts, and fitments |

| Aerospace | Measuring precision aircraft components, engine parts, and fitments |

| Automotive | Inspecting brake rotors, bearings, pistons, and chassis components |

| Medical | Designing implants, verifying surgical tools, and modeling anatomical structures |

| Agriculture | Measuring wear or part fit for heavy equipment |

| Laboratories | Measuring test samples, instrumentation, and small parts for research applications |

Choosing the Right Caliper for Your Application

When it comes to purchasing a caliper, consider:

- Accuracy requirements

- Environment (dusty, oily, humid, etc.)

- Measurement range and resolution

- User experience level

- Integration needs (USB, Bluetooth, data transfer)

If you’re still unsure, let us help. Check out our guide on How to Choose the Right Caliper to find the perfect fit for your team.

The Bottom Line: Precision Depends on the Details

Whether you’re working in a high-speed production environment or a quiet R&D lab, calipers are a foundational part of any measurement toolkit. By understanding their features, functions, and proper use, you’ll ensure that your measurements are always reliable, and your quality never compromised.

When it comes time for calibration, repair, or selecting the right equipment, Michelli Weighing & Measurement is your precision partner every step of the way.

Need Help Choosing or Calibrating a Caliper?

Let Michelli be your precision partner. Contact us today to schedule calibration or get expert help selecting the right tool for your team.