A Brief History of Multimeters

The multimeter has been a cornerstone of electrical testing since the early 1920s. Originally known as the “Avometer,” this device combined the functions of several instruments into one. Over time, analog needle-based models evolved into today’s digital multimeters (DMMs), offering improved accuracy, automatic ranging, and data logging capabilities.

From small electronics shops to industrial plants, multimeters remain indispensable for technicians diagnosing voltage drops, testing continuity, and ensuring safety in electrical systems.

How Multimeters Work

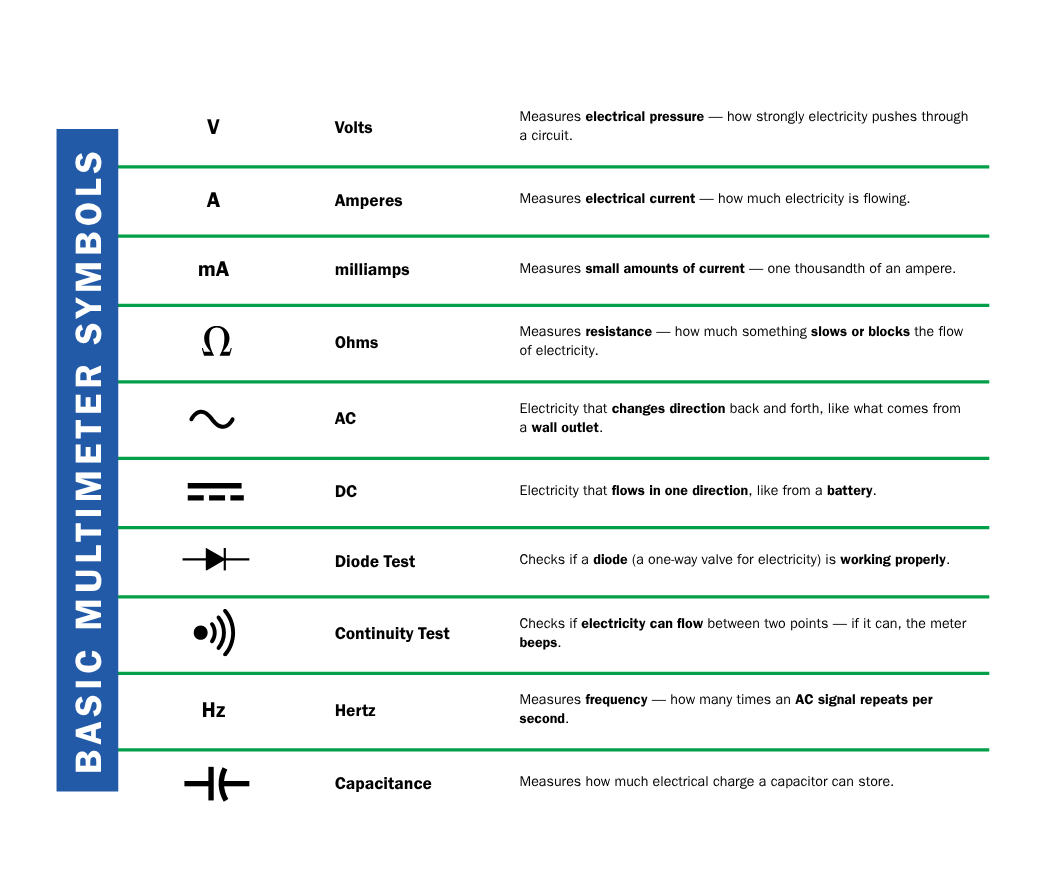

A multimeter measures three primary electrical properties — voltage, current, and resistance.

- Voltage (V): Measures the potential difference between two points.

- Current (A): Measures the flow of electric charge through a circuit.

- Resistance (Ω): Measures how much a component resists current flow.

Digital multimeters (DMMs) use internal analog-to-digital converters (ADC) to translate electrical signals into readable numerical values. Advanced models also test continuity, capacitance, frequency, and temperature.

Analog vs. Digital Multimeters

- Analog Multimeters: Feature a moving needle and scale. While durable, they can be harder to read precisely.

- Digital Multimeters: Display readings on an LCD, providing greater accuracy, ease of use, and additional measurement modes.

For precision work, especially in industrial or laboratory environments, digital multimeters are the standard.

Why Multimeter Calibration Matters

Even the most advanced instrument readings drift, or deviate from the known standard, over time due to environmental factors, aging components, or mechanical stress. Calibration verifies that a multimeter’s readings align with known standards, ensuring consistent accuracy and compliance.

Regular calibration:

- Identifies drift before it affects results

- Ensures compliance with ISO 17025 and other quality standards

- Reduces the risk of costly measurement errors

- Extends instrument lifespan

Michelli’s calibration experts use precision reference standards to test and adjust multimeters, verifying accuracy across all functions and ranges.

Understanding Accuracy, Resolution, Range, and Counts

When evaluating or calibrating a multimeter, four key specifications determine its performance:

- Accuracy: How close the displayed reading is to the true value.

- Resolution: The smallest change the instrument can detect.

- Range: The limits within which it can measure safely and accurately.

- Counts: The number of display digits a DMM can show (for example, 6,000 or 60,000 counts).

Maintenance & Safety Tips

To maintain reliable performance:

- Store multimeters in clean, dry environments.

- Verify the CAT rating before use to match application safety requirements.

- Check fuses, probes, and leads for wear or damage.

- Never exceed the instrument’s rated limits.

- Schedule periodic calibration (typically every 12 months).

- Read our blog post: How to Maintain Measurement Accuracy Between Calibrations.

High-accuracy applications, like aerospace or electronics testing, demand regular verification to ensure readings remain traceable to NIST standards.

Common Applications

Multimeters are vital across nearly every technical industry:

Electrical & Industrial Maintenance

Testing circuit integrity, motors, and control panels.

Manufacturing & Production

Quality control and troubleshooting electrical systems.

Laboratories

Research and device testing under controlled conditions.

Energy & Utilities

Monitoring power systems and verifying instrumentation performance.

Michelli: Your Partner in Precision

Michelli Weighing & Measurement provides accredited calibration, repair, and maintenance services for multimeters and other electrical test instruments. Whether you’re managing a single handheld device or a full fleet of meters, our experts ensure your tools meet the highest standards of accuracy, safety, and compliance.

From routine verification to ISO 17025-accredited calibration, Michelli helps you keep every measurement precise, because when it comes to reliability, accuracy matters.

Need help selecting or maintaining your multimeter?

Michelli’s experts are ready to assist with recommendations and calibration services tailored to your industry.