What to Know About a Calibration Laboratory

There are certain rules inside a calibration laboratory. The rules help ensure that the environment doesn’t interfere with calibration, as some equipment is highly sensitive to factors like temperature, moisture, and even oil produced by the human body. For example, a calibration laboratory is kept at a predesignated temperature, it’s kept clean, and most equipment is kept covered to avoid being contaminated by dust or other environmental factors. From temperature specifications to “look, don’t touch” areas, it’s important to understand the rules of the lab to ensure you don’t accidentally affect the environment or compromise the standards used to calibrate equipment.

The Michelli Weighing & Measurement Calibration Laboratory

The largest & busiest Michelli Weighing & Measurement calibration lab is located at our corporate office in Harahan, Louisiana, just outside of New Orleans on the Mississippi River.

The cal lab is divided into work spaces based on measurement disciplines. There are labels at the top of each station announcing which measurement disciplines are calibrated in that area. For example, in the “Weighing” station, scales are calibrated. In the “Torque” station, torque wrenches are calibrated.

Let’s take a look at each station & review the measurement discipline covered in each.

What Equipment is Located in Each Calibration Work Station?

There are “standards” in each work station. These standards are sent out for calibration regularly. This helps to ensure that the standard is accurate, and to ensure the validity of all equipment calibrated using the standard. During a calibration, the equipment being calibrated is compared to the standard, then adjusted until the 2 match when prompted with the same input.

Calibrating equipment is sort of like tuning a guitar. The measurement equipment that requires calibration is like the guitar that is out of tune. The standard is like the guitar that has been certified to be in tune. Our calibration technicians bring the measurement equipment back into “tolerance”, just as a musician might bring a guitar back “in tune”.

Temperature Calibration Work Station

In the Michelli Weighing & Measurement temperature calibration work station, we service the following types of equipment:

Contact Thermometers

• Thermocouple Probes

• Thermistor Probes

• Resistance Temperature Detectors (RTD)

• Bi-Metal Thermo-Wells

• Liquid–in–Glass (LIG)

• Surface Thermometers

• Tank Thermometers

Temperature Calibrators

- Thermocouple Calibrators

- RTD Calibrators

- Dry Well Calibrators (Dry Block)

- Liquid Baths

Non-Contact Thermometers

- Infrared Thermometers

- Psychrometers

- Weather Stations

- Heat Stress Monitors

Temperature measurement instruments are important across many industries. An inaccurate thermometer or heat stress monitor could affect worker safety in a hazardous work environment, or even consumer safety in the food & beverage industry. Temperature measurement equipment is incredibly important to many industries & ensuring that equipment is calibrated properly could mean a matter of life & death.

Pressure Calibration Work Station

In the Michelli Weighing & Measurement pressure calibration work station, we service the following types of equipment:

- -30 to 100 PSIG with accuracy up to +/-0.025%

- 0 to 1000 PSIG with accuracy up to +/-0.025%

- 0 to 5000 PSIG with accuracy up to +/-0.05%

- 5000 to 40000 PSIG with accuracy up to +/-0.1%

- Pressure Gauges

- Pressure Transmitters

- Pressure Switches

- Pressure Valves

Pressure measurement equipment is extremely important in many industries. For example, a pressure gauge used in the petrochemical industry could indicate to the crew that they have entered into a dangerous situation, allowing them time to change course & correct the issue. That pressure gauge undergoes intense vibration & could be exposed to the elements, leading to corrosion. It’s imperative that the equipment remains within tolerance so that the crew will know the readings are accurate.

Physical/Dimensional Calibration Work Station

In the Michelli Weighing & Measurement physical/dimensional calibration work station, we service the following types of equipment:

Micrometers

• Outside micrometers

• Inside micrometers

• Depth micrometers

• Analog or Digital

• Up to 80 inches

Indicators & Other

- Travel indicators

- Test indicators

- Starrett Last Word indicators

- Height Gauges

- Calipers

- Dial or digital indicators

- Snap gauges

- Length standards

Granite Surface Plates

Dimensional measurement equipment is used in almost every industry at some point. Some dimensional measurement equipment is used in the manufacturing of other equipment, like micrometers for example. Calibration of this equipment is crucial to ensuring that the tools can be used to meet exact specifications. For example, a micrometer may be used during the manufacturing of component parts in the aerospace industry. Those component parts need to be a very specific size, shape & thickness to function properly, so it’s incredibly important that the dimensional tools used during the component manufacturing process have been properly calibrated.

Torque & Bolting Tool Calibration Work Station

In the Michelli Weighing & Measurement torque calibration work station, we service the following types of equipment:

-

- Mechanical “click” and dial type torque wrenches

- Cam-over drivers and wrenches

- Digital-pulse torque tools

- Pneumatic bolting tools

- Hydraulic bolting tools (up to 25,000 ft-lbs in-house)

- Hydraulic power pump services

- Pneumatic nut runners

Torque & bolting tools are used in many applications. Torque wrenches are actually precision instruments, with intricate components inside the shaft of the wrench. These components are very sensitive, but torque wrenches are often used in rugged environments like tire shops. If the torque wrench has been dropped, or is for some other reason out of tolerance, using it to install tires presents a truly dangerous situation for both the installer & the driver of the vehicle. For more information on proper torque wrench care, please see our earlier blog post Torque Wrench Care Tips here.

Electronic Calibration Work Station

In the Michelli Weighing & Measurement electronic calibration work station, we service the following types of equipment:

Electrical Testing

• Digital Multimeters

• Process Meters

• Ammeter/Clamp Meters

• MegOhmMeters

• MicroOhmMeter (DLRO)

• Phase Meters

• Volt/Ohm/Milliamp Meter

• R/L/C Meters

• High Voltage Dielectric Test Sets (Hipot) up to 100 kV

Process Instruments

• Power Quality Analyzers

• Signal Analyzers

• Frequency Analyzers

• Loop Calibrators

• T/C & RTD Calibrators

• Multifunction Process Calibrators

Time & Frequency

- Oscilloscopes

- Timers

- Stopwatches

- Frequency Counters

- Arbitrary Waveform Generators

Electrical testing equipment is used in situations where electrical currents may be present. For example, electricians use various tools to test the existence of electrical currents, as well as the voltage, frequency & other information that could affect safety. Some of the electrical testing equipment listed is used to translate the information received into readable information we can use, such as the graphs produced by an oscilloscope.

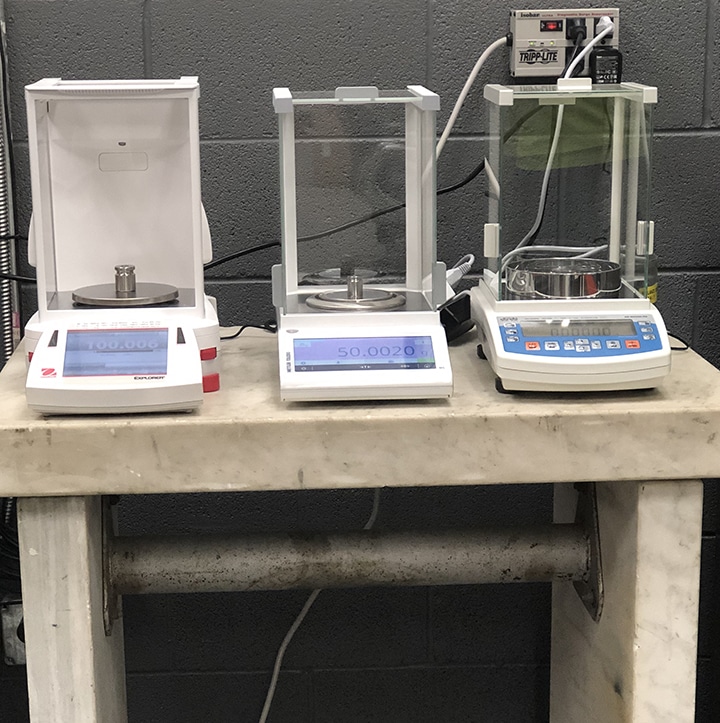

Lab Balance & Scale Calibration Work Station

In the Michelli Weighing & Measurement lab balance & scale calibration work stations, we service the following types of equipment:

- Top loading & analytical laboratory balances

- Bench scales

- Floor scales

- Drum-filler systems

- High-speed grading systems

- Tank/hopper scales

- Truck scales

- Rail scales

- Counting scales

- Checkweighers

- In-Motion scales

Weighing equipment is used across all industries. From truck scales that determine whether or not a load is too heavy to travel on the road to counter scales that ensure you’re buying an actual pound of coffee, weighing is part of our everyday lives. Laboratory balances are used in many industries. In the pharmaceutical industry for example, lab balances are used to ensure the correct amounts of drugs are being combined to produce different types of medicine. Life or death could depend on the accuracy of the lab balance, so regular calibration is imperative.

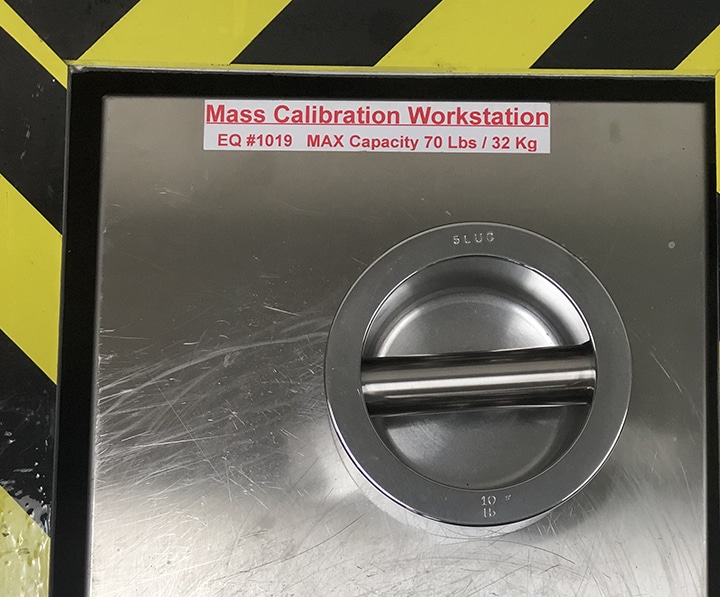

Mass Calibration Work Station

In the Michelli Weighing & Measurement mass calibration work station, we service the following types of equipment:

- NIST Class F test weights up to 50lbs or 30kg*

- NIST Class F analytical mass, 1 milligram to 1 kilogram

Mass measurement equipment is used across many industries. NIST test weights are considered mass measurement instruments. These test weights are used to calibrate scales, or check that the scales are still in tolerance between calibrations. It’s important that these test weights are properly calibrated, as they are being used as the standard to which other calibration equipment is compared. If they are not properly calibrated & are out of tolerance, then every piece of equipment calibrated with them is also going to be out of tolerance.

Force Measurement Calibration Work Station

In the Michelli Weighing & Measurement force calibration work station, we service the following types of equipment:

- Dynamometers (electronic and mechanical)

- Load cells (tension & compression)

- Crane scales

- Force gauges (electronic and mechanical)

- Force sand fixtures

- Multi-load cell telemetry systems

- Custom proof-load testing

Force measurement equipment is used in proof testing applications, transportation & logistics, manufacturing & even the food & beverage industries to name a few. Force measurement equipment can be used to weigh cargo as it is loaded from a dock to a boat. The weight being displayed by the force measurement instrument will affect whether or not the object being lifted can safely be used, moved or lifted. It’s imperative that the force measurement equipment has been properly calibrated to ensure the safety of everyone involved.

Calibration is Important

At Michelli Weighing & Measurement, we take calibration seriously. Michelli calibration technicians are trained in multiple disciplines, and reference calibration manuals produced by the U.S. military, the National Institute of Standards & Technology (NIST), as well as manufacturer specifications & product manuals. Our calibration team fully understands how each piece of weighing & measurement technology works, what issues to watch out for, and what factors cause equipment issues. As a result of that knowledge, the calibration laboratory rules are followed very closely, and guidelines are taken very seriously.

As you can see, our capabilities extend far beyond scale calibration. Are you using multiple vendors for your weighing & measurement equipment calibration? That means you’re dealing with multiple invoices, keeping track of multiple calibration schedules on your own, and scheduling with several companies to get all service calls scheduled. Are you ready to ease your stress & reduce your workload? Let the experts at Michelli handle all of your weighing & measurement related needs. From sales & rentals to service & calibration, we can help. Request a quote online today.

Let us take care of your calibration

We’re here to help with all of your weighing & measurement equipment calibration needs. Contact your nearest Michelli office today to request a quote or speak with an expert.