Michelli Weighing & Measurement Blog

Setting the Standard in Quality Service Since 1947The Michelli Weighing & Measurement blog is full of helpful information from our experts & the manufacturers we represent.

Tips to Protect Scales & Decrease Risk

A quality scale for your business can be a significant investment that will prove to be imperative during day to day operations. The best way to protect that investment is to treat the scale as the valuable tool that it is. Doing so will ensure you get the longest possible life out of your investment. A great way to protect scales is to routinely perform preventative maintenance, including calibration, greasing load cells, cleaning under the scale & more.

A&D Inspection | Choosing Product Inspection Equipment for Food Safety

High quality product inspection equipment is incredibly valuable. Learn how to choose the right inspection equipment for your operation & what factors to consider when choosing equipment. Plus, learn what makes A&D inspection checkweighers unique, and how the A&D checkweigher data can help you increase productivity.

How to Protect Your Electronics from Electrostatic Discharge (ESD)

Electrostatic discharge, or “ESD”, occurs when static electricity is suddenly transferred between two electrically charged objects. ESD is incredibly common, and although it isn’t always noticeable to humans, it can still be powerful enough to harm or ruin electronics. Learn the best ways to protect your equipment in this post.

An In-Motion Checkweigher Can Help With Quality Assurance

In-motion checkweighers are often used in production lines, where they are incorporated into weighing systems to create an automated quality assurance process. Learn how weight can be used in quality assurance, and how weighing systems help increase efficiency & maximize productivity.

Dillon Force | The Dillon Dynamometer

Dillon dynamometers come in three types, including the AP Dynamometer, the EDjunior Dynamometer, and the EDXtreme Dynamometer. Because each of these models is designed with different specializations in mind, there’s sure to be a dynamometer for every job. Let’s take a closer look at each of the models to help you determine the best option for your application.

B-TEK Scales | Truck Scale Challenge | Calculating the Steel

When it comes to truck scales, most manufacturers produce a quality scale weighbridge with a lot of steel, that will last for years … and all boast that they are the strongest, toughest and longest lasting one available. In a market with so many options, how can you actually determine who backs up that statement? The simplest way to do this is to determine who uses the most steel to construct the scale. To do this, we simply determine the weight.

Things to Consider Before Buying a Scale Online

It’s always best to work with a professional to determine the best type of equipment for your application. Websites are great for commodities, but not for equipment that contributes to pricing, quality or other product attributes. Online purchases could actually lead to a much higher price tag than anticipated after figuring in set up costs, replacement parts, or repairs. Here are some factors to consider before clicking “Add to Cart”.

All about Torque Multipliers

A torque multiplier enables users to apply greater torque without requiring any additional strain on the operator. The use of torque multipliers can increase productivity & efficiency by greatly reducing the amount of effort required to get fasteners to tighten or loosen.

Mountz | Guide for Selecting a Precision Torque Wrench

Whether you’re in manufacturing or maintenance, the most important attributes your torque wrench should have are quality and reliability. And the best way to be sure the wrench you’re investing in will hold up on the line is to choose the right torque wrench technology. Let’s examine click wrenches vs. cam-over wrenches to help you select the correct Mountz torque wrench.

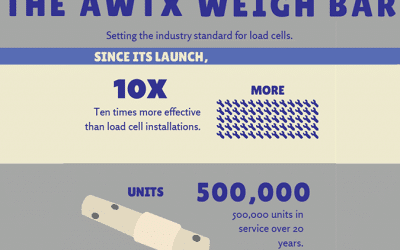

Avery Weigh-Tronix | Proper Weighing Technology is Key to Maximizing Efficiency

The proper use of weighing technology can be an efficient means of monitoring the transportation of goods. Such technology has a wide range of uses and applications, the key to which is Avery Weigh-Tronix’s Weigh Bar. Over several decades, the Weigh Bar has built a reputation for precision, reliability, and durability that no other load cell can match.

How to Choose the Right Caliper

Each type of caliper utilizes a different output method for communicating the measurement reading to the user. The type you should choose depends on the application in which the tool is being used & user preference. Let’s examine the three basic types of measurement calipers to develop a better understanding.

Starrett | DataSure® 4.0 – Advanced Data Collection System Made Simple

Data collection has never been easier. Starrett DataSure® 4.0 modernizes & streamlines collection of quality control measurement data. With DataSure 4.0, the press of a button can transmit measurement data, improving process efficiency and the accuracy of measurements captured. Learn more in this post about the transformative advantages of this system from Starrett.